Sheet metal followers support

The follow-up material dragging device for bending machines is an important equipment used to assist bending machines in sheet metal bending processing, which can effectively improve processing precision and production efficiency. SMS provides a full range of models for customers to choose from, so as to meet the diverse needs of different customers.

Read MoreWork Principle

The bottom servo motor drives the rack and pinion. Through the adjustable lever connector at the top of the rack, it pushes the tabletop to rotate around the center to achieve bending follow-up; the lever structure can evenly distribute the load to each joint, ensuring the mechanism's precision and stable, efficient rotation.

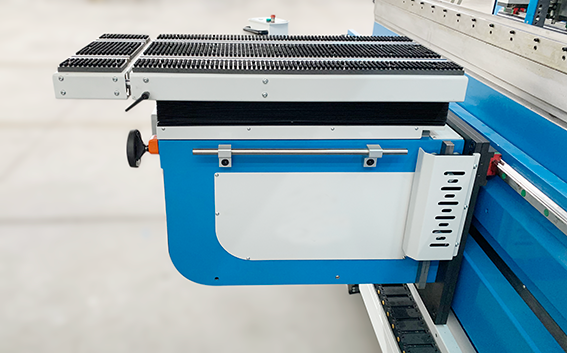

Request A InformationIntegrated Follow-Up Front Material Support

It is integrated with the bending machine, and mounted on the lower crossbeam via the base, guide rail slider and cam, allowing horizontal sliding along the Z-axis. Controlled directly by the bending machine's numerical control system, it can adjust the vertical position of the support tabletop as well as the horizontal positions along the Z-axis and X-axis during the bending process.

- High-precision positioning: real-time monitoring (encoder + laser ranging), 10ms servo adjustment, micron closed-loop control, anti-sheet springback.

- Improve production efficiency: automatic material following eliminates manual intervention, intelligent avoidance optimizes paths, and multi-axis synchronization reduces idle strokes

- Suitable for complex processes: 6-degree-of-freedom fixtures, 3D visual compensation, with a yield rate of over 98% for special-shaped parts; air-floating material support prevents scratches on ultra-thin aluminum plates

- Easy operation: The bending machine's numerical control system controls the zero point, follow-up, and return stroke status, which only needs to be set in the system.

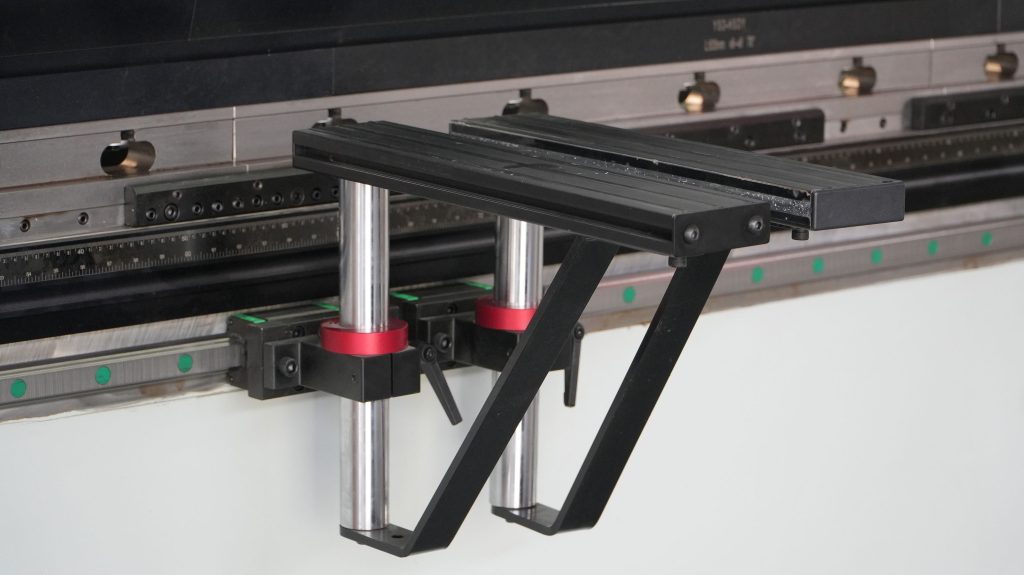

Floor-Mounted Follow-Up Front Material Support

It moves to the working position via rollers, is fixed at a proper position on the ground with foot supports, and is equipped with an independent programmable controller, which can be used with various models of bending machines.

- Suitable for large size sheet metal bending, reduce artificial.

- Improve machine tool processing efficiency ,ensure the accuracy of bending Angle.

- Accurately read the displacement data of Y axis and keep 100% synchronization with Y axis.

- Independent control system, No need to upgrade the original system of the bending machine.

- Suitable for matching with various types of bending machines.

- Adjust the up and down movement according to the height of the die, and the size of the V port.

- Equipped with a brush table to prevent any sheet from being scratched, slipped or dropped.

- Flexible and easy to use, easy to load and unload, Realize a multi-platform sharing mode with moving.

Simple Support

The simple material support device for bending machines is an auxiliary equipment with a relatively simple structure and low cost. It is mainly used to assist in supporting and positioning sheet metal, so as to improve the efficiency and quality of bending processing.

- Reduce labor intensity: No need to manually support the sheet metal, which reduces intensity and improves efficiency.

- Improve precision: The material support plate provides support and positioning, reducing bending sagging and deviation.

- Simple structure, low cost: Simpler than follow-up supports, lower cost, suitable for low-precision SMEs.

- Easy operation: Control the start and stop of the motor and push rod, easily adjust the height position of the material support plate, and the process is simple.