Professional Bending Machine Solutions

Our advanced bending technologies cater to diverse industrial needs, delivering consistent performance even in the most demanding production environments.

Browse ProductsRequest A quote

20 +

Years of Experience

500 +

Machines Delivered

20 +

Country Served

98 %

Customers Satisfaction

Leading Supplier of sheet metal Machinery

- Advanced Technology:Our sheet metal machinery incorporate the latest CNC technology and hydraulic systems for unmatched precision

- Global Presence:With distribution networks across 20+ countries, we provide localized support and service to clients worldwide.

- Quality assurance:All our machines undergo rigorous testing and meet international standards and 48 hours testi

Our Press Brake Series

A comprehensive range of bending solutions designed to meet diverse industrial requirements with precision and efficiency.

Request A quoteCNC electro Hydraulic Press Brake

- Repeat Positioning Accuracy: ±0.01mm

- Energy-saving Design

- processing complex workpieces

Normal Hydraulic Press Brake

- durable with low maintenance costs

- Simple operation, easy to get started

- Suitable for batch standardized production

CNC Hybird Servo press Brake

- Energy saving can reach more than 40%

- Low-noise design

- More stable oil temperature control

CNC Pure Electro Press Brake

- Zero emissions, environmentally friendly

- High-precision position contro

- Low maintenance costs

CNC Tandem Link Press Brake

- processing workpieces over 12 meters

- synchronization accuracy: ±0.02mm

- Intelligent collaborative control system

Bending System for Light Poles

- Algorithm for Tapered Workpieces

- Fully Automatic Feeding and Positioning

- 30% Increase in Production Efficiency

How to select a suitable press Brake?

Selecting the appropriate bending machine depends on your specific application requirements and production needs.

Select NowRequst A helpKey Considerations for Selection

- Material and Thickness: Consider the type of material (steel, aluminum, etc.) and its thickness. Heavier materials require higher tonnage machines.

- Workpiece Length :Choose a machine with a bending length suitable for your longest workpiece, with some margin for flexibility.

- Complexity of Bends: Simple bends may only require 2-3 axes, while complex parts with multiple angles need 4+ axes and CNC capabilities.

- Production Volume: High-volume production benefits from advanced CNC models with faster setup times and automation capabilities.

- Energy Efficiency: For environmentally conscious operations or high-energy cost regions, consider hybrid or full electric models.

Machine Selection Guide

- Simple Bending Tasks: SPT Normal Hydraulic Press Brake (2-3 axes) is ideal for basic bending requirements with standard materials.

- Precision & Complex Bends: SPE CNC Electro Hydraulic (4-8 axes) or SBK Hybrid Servo (4-12 axes) for intricate parts with tight tolerances.

- Energy Efficiency Priority: SPD CNC Pure Electro Press Brake offers the highest energy savings and clean operation.

- Extra-Long Workpieces: SDL CNC Tandem Link Press Brake provides synchronized bending for extended length materials.

- Light Pole Manufacturing: SPL Specialized Bending System is purpose-built for pole production with optimized programming.

Not Sure Which Machine Fits Your Needs?

Our technical experts can analyze your specific requirements and recommend the optimal bending solution for your production line.

Schedule a ConsultationCustom & Non-Standard Bending Solutions

- Tailored Design Approach: Our engineering team works closely with clients to understand specific requirements and develop customized solutions that integrate seamlessly with existing production lines.

- Industry-Specific Solutions: We've developed specialized bending systems for aerospace, automotive, construction, and energy sectors, addressing unique material and precision requirements.

- Complete Turnkey Projects: From initial concept through installation and training, we manage custom projects end-to-end, ensuring successful integration and operation.

Extended Lengths

High Tonnage

Special Tooling

Special Voltage

Automation Integration

Special Environments

Precision Manufacturing Process

Every SMS bending machine undergoes a strict manufacturing process to ensure outstanding quality and performance.

Read MoreMachine Design

- 3D modeling and simulation analysis

- strength and stiffness optimization design

- ergonomic design

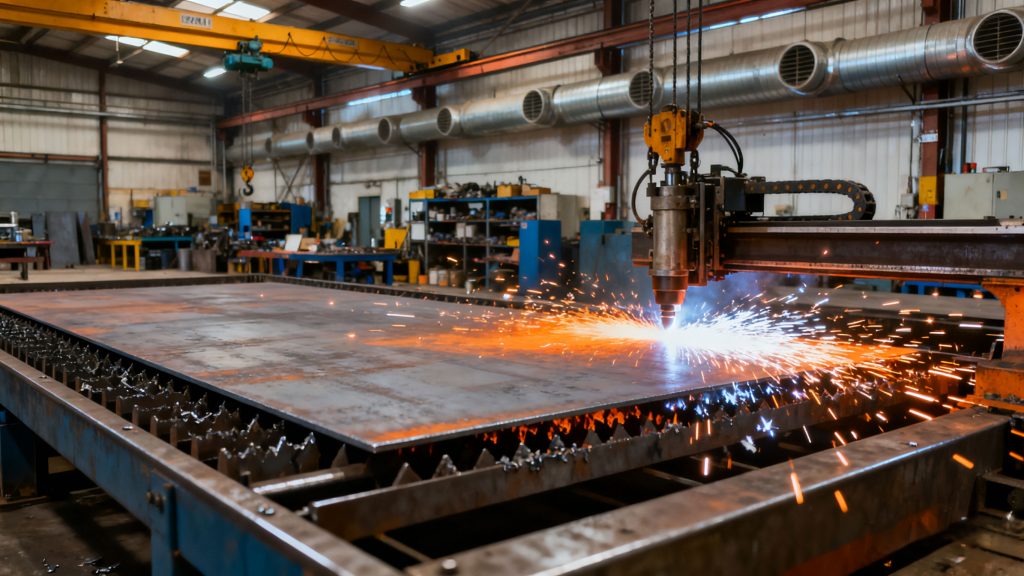

Raw Material Cutting

- High-precision Plasma/Laser Cutting

- Integral Quenching Treatment, with Hardness Reaching HRC 50-55

- Material Stress Relief Treatment

Slider and Frame Finish Machining

- Control Key Geometric Tolerances.

- Ensure Uniform Transmission of Bending Force.

- Reduce Surface Roughness (Ra.

- Ensure Uniform Fitting Clearance.

- Optimize Structural Rigidity

Welding of the main frame

- Robot-assisted welding ensures consistency.

- 100% non-destructive testing (NDT) for weld seams.

- Vibratory stress relief to eliminate internal stress.

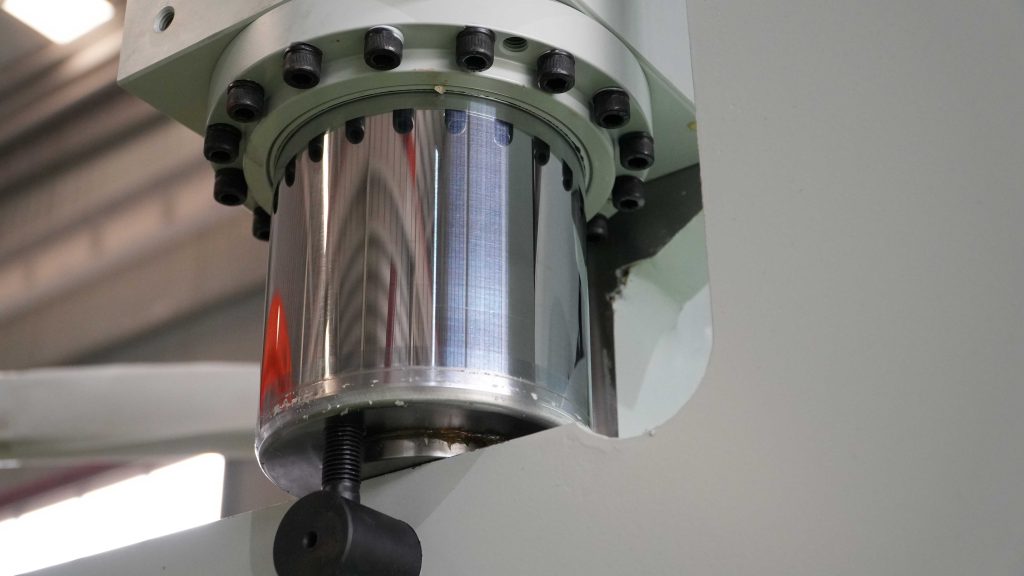

Oil Cylinder

- Process: Alloy Forging + 5-Axis CNC Machining (Tolerance: ±0.02mm, Ra 0.4μm).

- QC: 1.5x Pressure Seal Test (30min no leakage), 28 Inspection Items (100% compliance).

- Performance: For steel plates ≥30mm, 15% faster response, service life >8000h (wear resistance HV800+).

Long guide rail design

- High Precision: Micron-Level Positioning via Rolling Friction

- Excellent Efficiency: High-Speed Slide Movement Enabled by Low Resistance

- Long Service Life & Easy Maintenance

- Flexible Adaptability: Modular Selection & Easy Assembly

Integrated Hydraulic System

- Precision: Dual closed-loop servo system, error ±0.01mm, compatible with 0.1-50mm workpieces.

- Power: Self-developed pump (31.5MPa), torque 20% above industry avg., bending force 100-3000kN.

- Stability: Core components (int'l brands), MTBF >8,000h, maintenance cost down ≥40%.

- Energy Efficiency: Load-sensing circuit, energy consumption reduced by 25%-35%

- Efficiency: Slide block no-load speed of 150mm/s, dual-cylinder synchronization of ±0.02mm

Aluminum Alloy Beam

- Lightweight Advantage: Reducing Load, Lowering Energy Consumption.

- High Rigidity: Resisting Deformation & Maintaining Positioning Accuracy.

- Easy Maintenance: Corrosion Resistance & Extended Service Life.

- High Precision: Easy Machinability & Stable Accuracy.

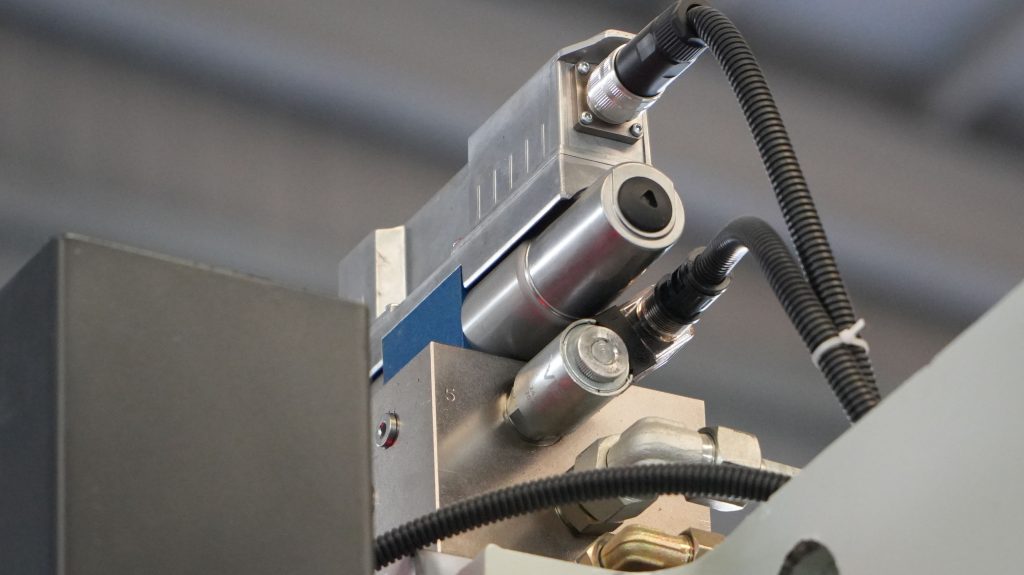

Quality and fast backgauge

- High-strength alloy crossbeam: anti-deformation, smooth position adjustment.

- Surface treatment: reduces friction, boosts corrosion resistance, cuts costs.

- Dual adjustment (electric + manual): Electric (CNC-integrated, accuracy ±0.02mm)

- Suitable for batch processing; manual adjustment: emergency convenience.

- High-low temp, durability & multi-workpiece tests done for long-term precision.

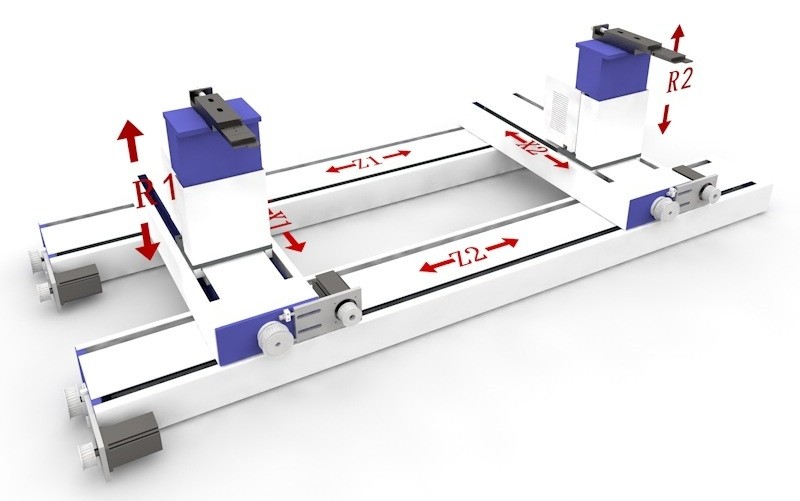

Multi axis control backgauge

- X-axis:direction of the bending machine (moving left and right)

- Z-axis: Along the vertical direction (moving up and down)

- R-axis: Along the vertical direction (moves up and down independently)

- Extended Axis: Along a specific direction

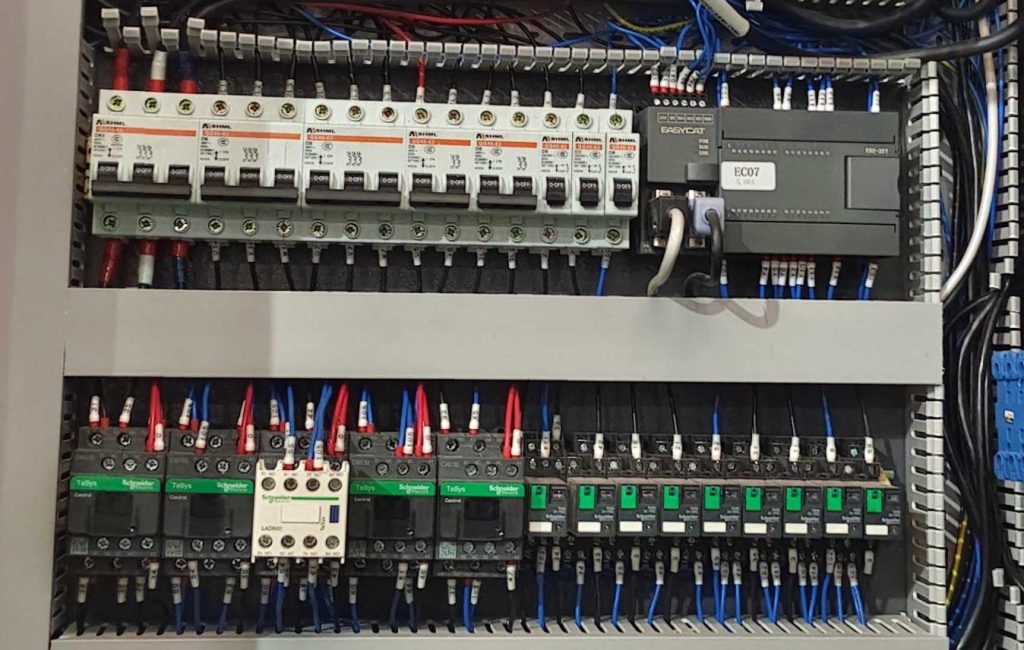

Electrical Cabinet

- Stable Control: Imported core PLC, signal response <0.1s, control accuracy ±0.02mm

- High Safety: IP54 compliant, overload/short-circuit protection, fault tripping <0.05s

- Environmental Resistance: Stable at -20℃~60℃, dust/humidity adaptability > industry standards