Professional Shearing Machine Solutions

As a professional hydraulic shearing machine manufacturer, SMS Machinery is committed to providing efficient, precise, and durable shearing solutions. These solutions cater to various metal processing needs and help enhance your production efficiency.

Browse ProductsRequest A quote20 +

Years of Experience

500 +

Machines Delivered

20 +

Country Served

98 %

Customers Satisfaction

Leading Supplier of sheet metal Machinery

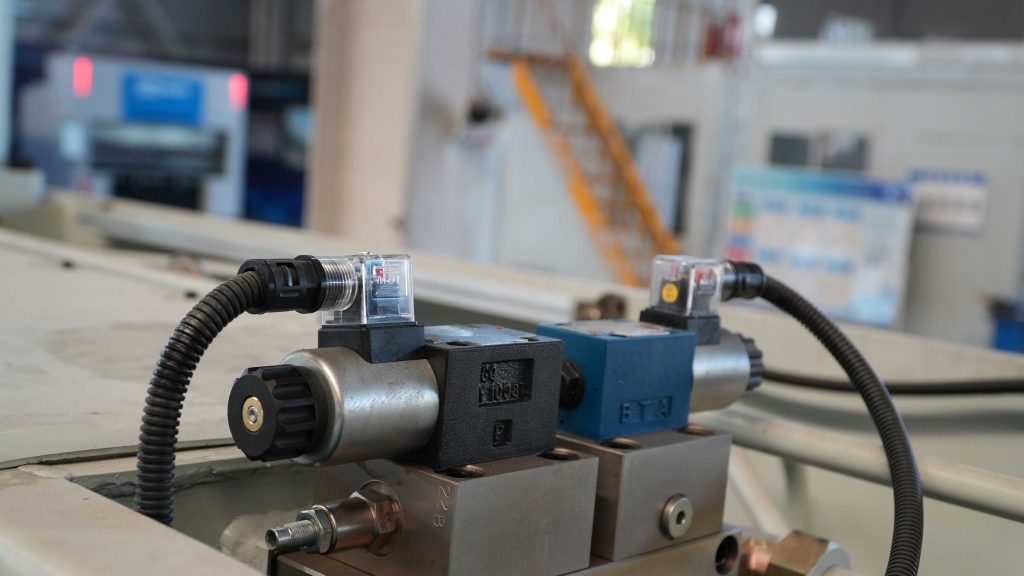

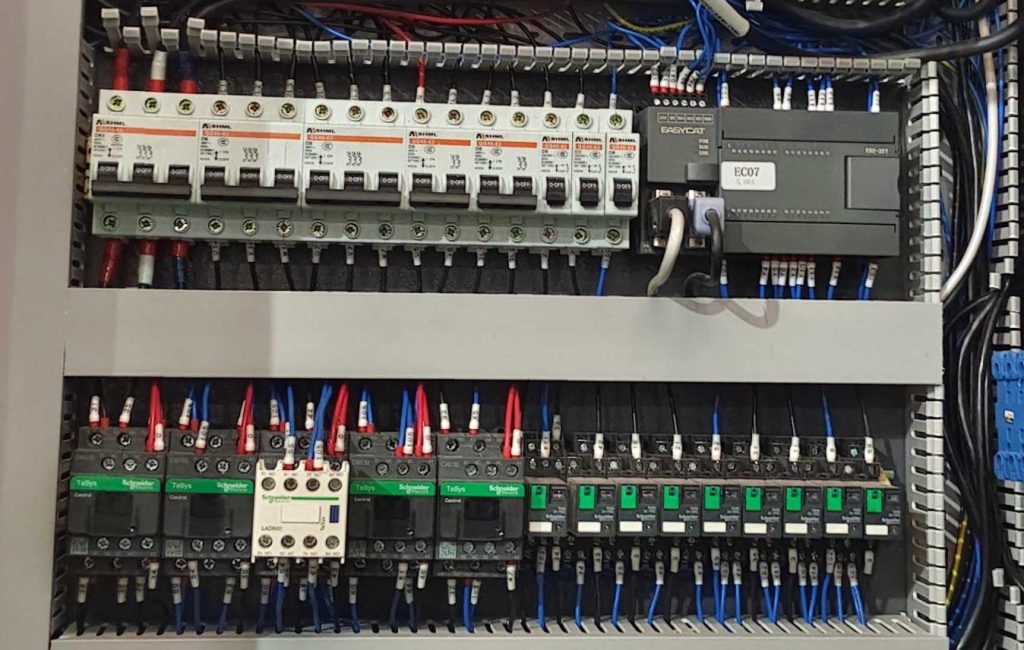

- Advanced Technology:Our sheet metal machinery incorporate the latest CNC technology and hydraulic systems for unmatched precision

- Global Presence:With distribution networks across 20+ countries, we provide localized support and service to clients worldwide.

- Quality assurance:All our machines undergo rigorous testing and meet international standards and 48 hours testi

Main Features of the Product

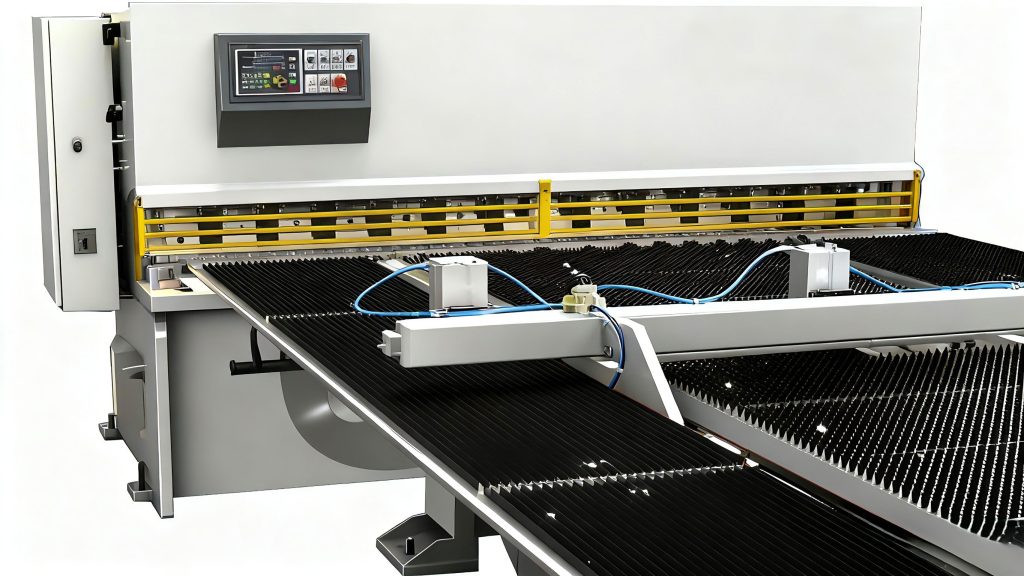

SMS Hydraulic Shearing Machine integrates advanced technology and precision manufacturing, providing you with an excellent shearing experience and reliable performance guarantee.

Request A quoteEfficient Hydraulic System

Ultra-High Shearing Precision

Multiple Safety Protections

Intelligent Control System

Adjustable Shearing Angle

Durable Structure

Not Sure Which Machine Fits Your Needs?

Our technical experts can analyze your specific requirements and recommend the optimal shearing solution for your production line.

Schedule a ConsultationCustom & Non-Standard Bending Solutions

- Tailored Design Approach: Our engineering team works closely with clients to understand specific requirements and develop customized solutions that integrate seamlessly with existing production lines.

- Industry-Specific Solutions: We've developed specialized bending systems for aerospace, automotive, construction, and energy sectors, addressing unique material and precision requirements.

- Complete Turnkey Projects: From initial concept through installation and training, we manage custom projects end-to-end, ensuring successful integration and operation.

Extended Lengths

High Tonnage

Special Tooling

Special Voltage

Automation Integration

Special Environments

Precision Manufacturing Process

Every SMS Shearing machine undergoes a strict manufacturing process to ensure outstanding quality and performance.

Request A quotdMachine Design

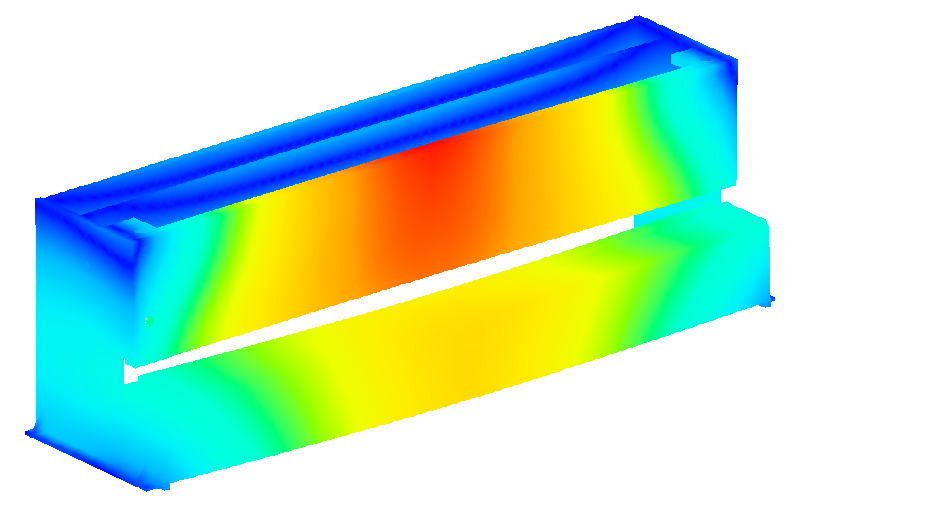

- 3D modeling and simulation analysis

- strength and stiffness optimization design

- ergonomic design

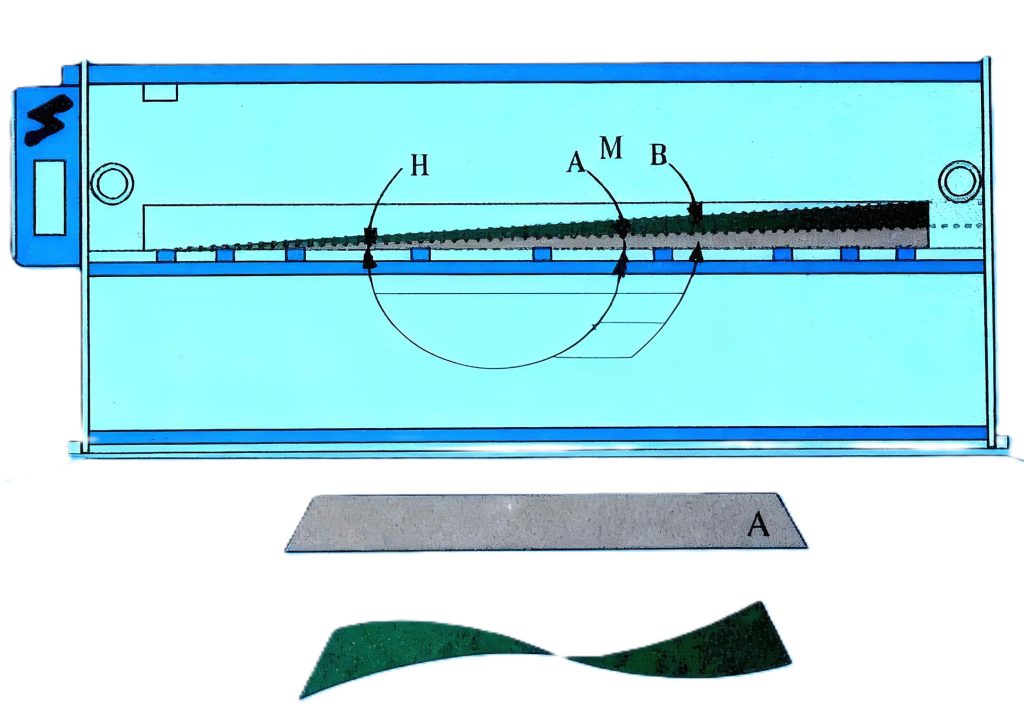

Adjustable Shearing Angle

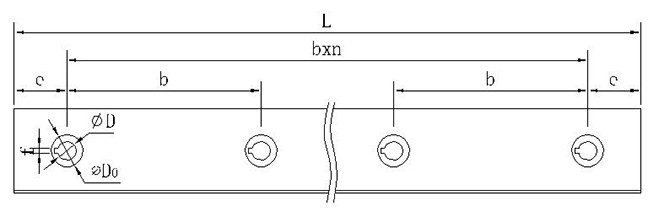

Blade Holder

Blade

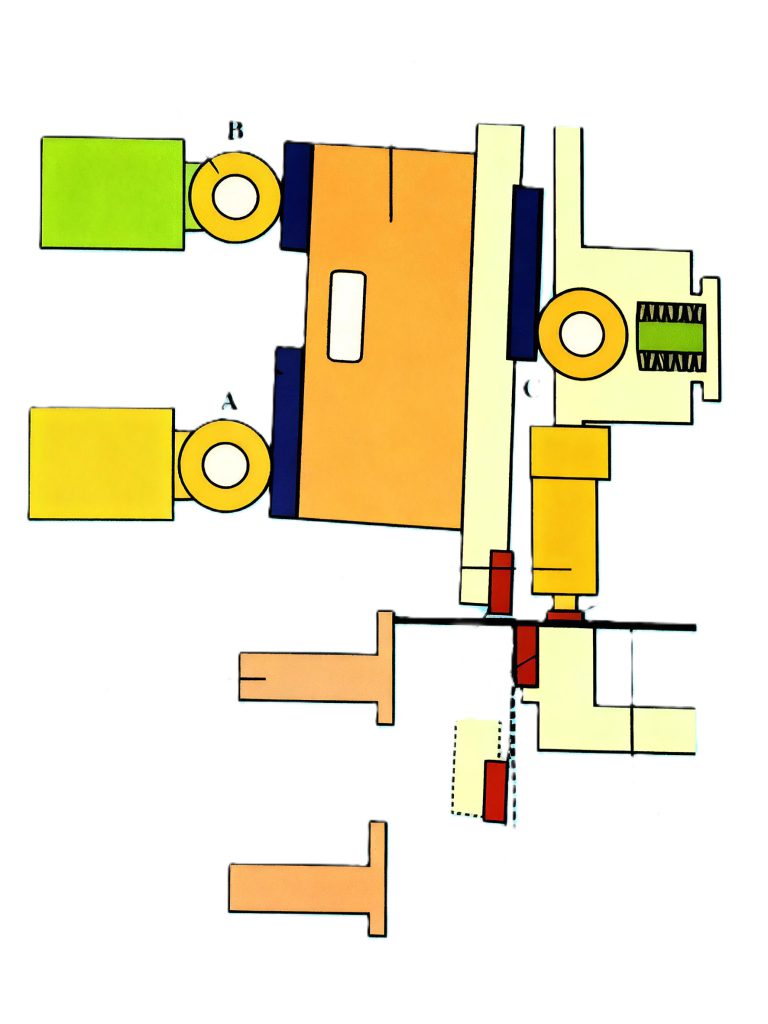

Oil Pump

Integrated hydraulic system

Centralized operation station

Backgauge lifting device

Electric Cabinet

CNC Front Feeding (Option)

Pneumatic rear support (option)