Professional Automatic Deburring Machine Supplier

Automated Deburring Solutions in the Precision Manufacturing Field Automated deburring solutions in the precision manufacturing field can efficiently remove burrs from workpieces, enhance product quality and production efficiency, and reduce labor costs.

Browse ProductsRequest A quote20 +

Years of Experience

500 +

Machines Delivered

20 +

Country Served

98 %

Satisfaction

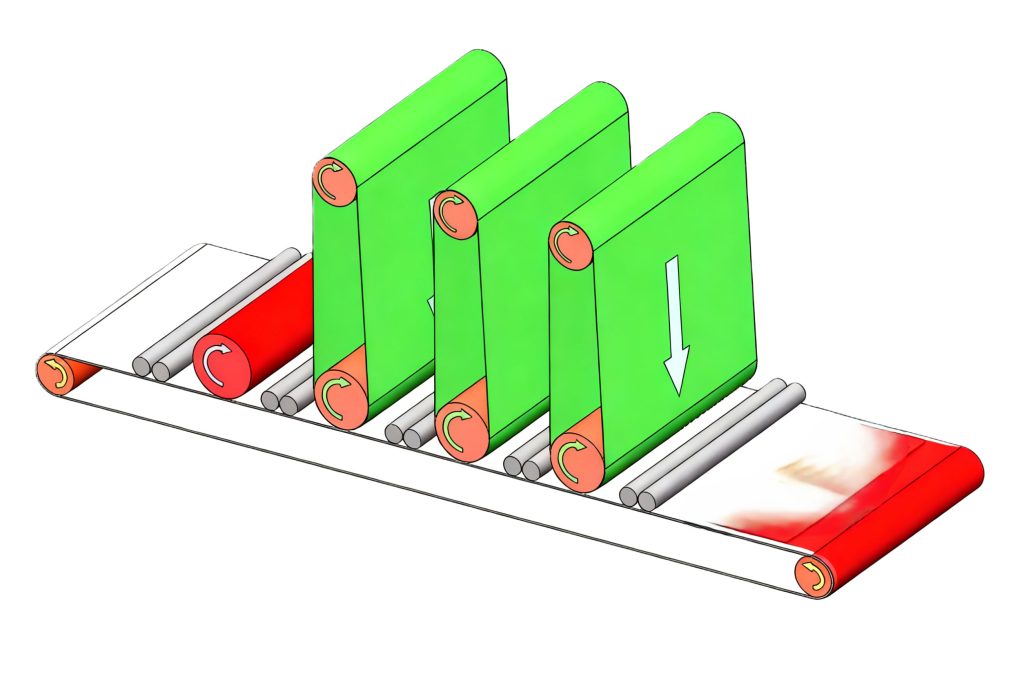

Core Features of the Deburring machine

Integrating advanced technology with precision manufacturing, we provide you with efficient, stable, and intelligent deburring solutions.

Contact usEfficient Deburring

Adopting a multi-axis linkage design, it completes multi-surface deburring in one go, with efficiency improved by more than 300% compared to traditional manual work.

Precision Machining

The repeat positioning accuracy reaches ±0.01mm, ensuring the consistency of deburring and improving the stability of product quality.

Intelligent Control System

Equipped with a touchscreen human-machine interface (HMI), it features simple operation, can store more than 100 sets of processing parameters, and enables quick switching between different workpieces.

Multiple Safety Protections

Equipped with multiple safety devices such as safety light curtains, emergency stop buttons, and overload protection, it ensures the safety of operators.

Flexible Design

It allows for quick fixture replacement, adapts to the deburring needs of workpieces with different shapes and sizes, and features short changeover time.

Cooling and Lubrication System

Equipped with a built-in high-efficiency cooling and lubrication system, it extends the service life of tools and effectively removes chips generated during processing.

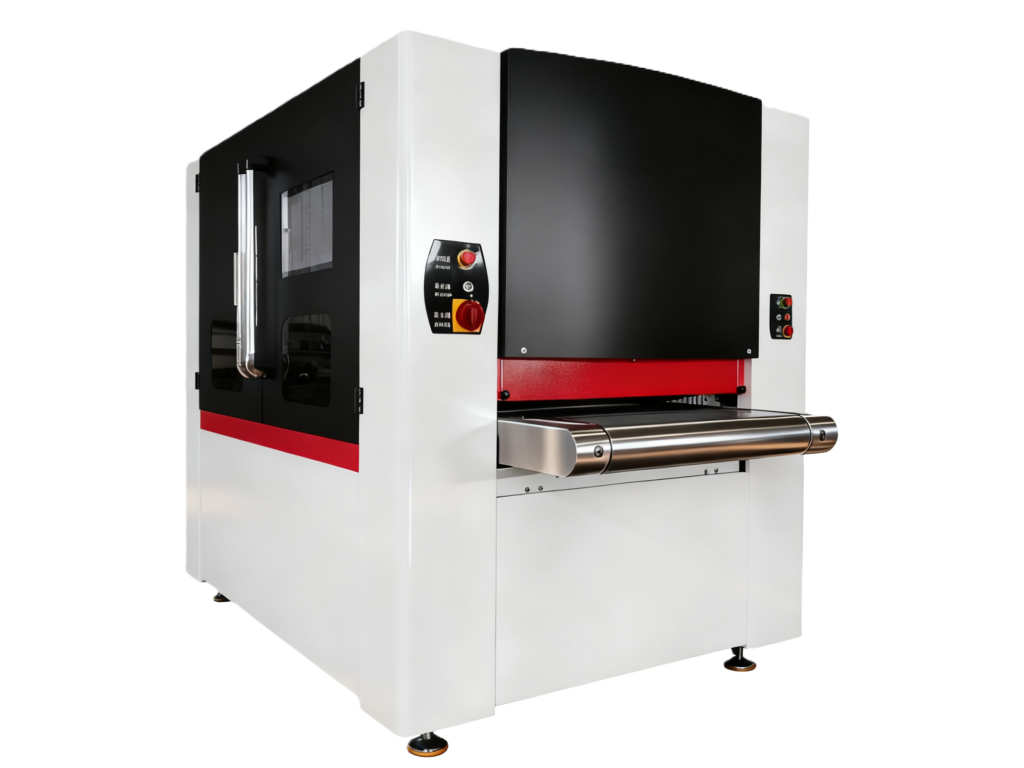

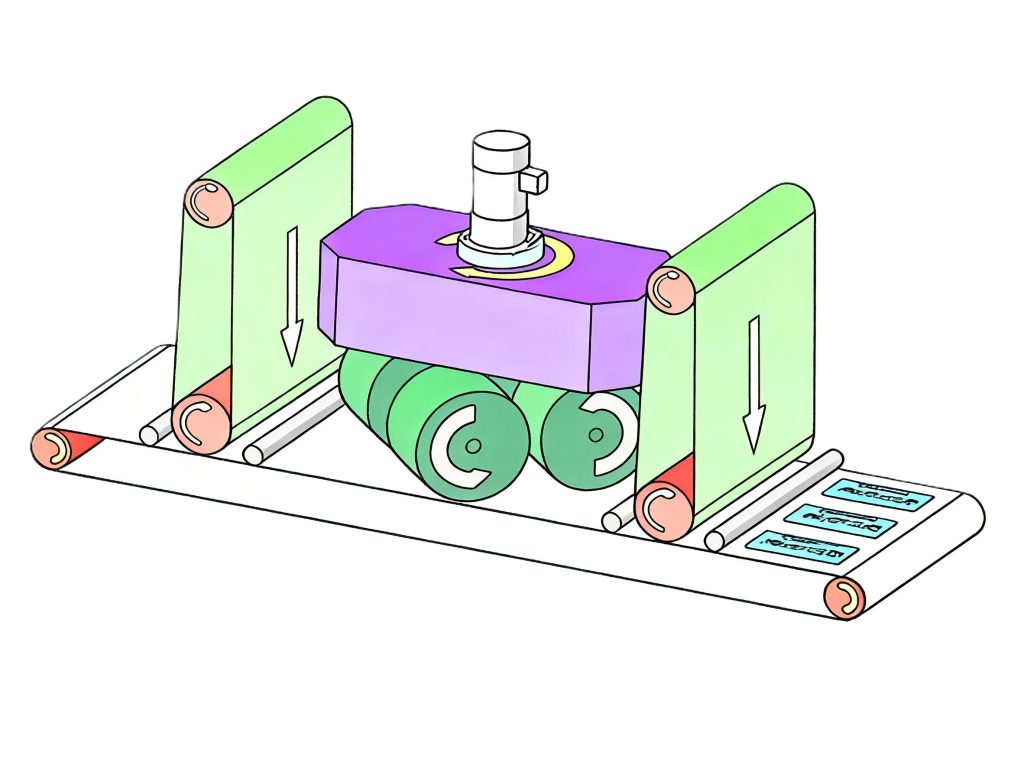

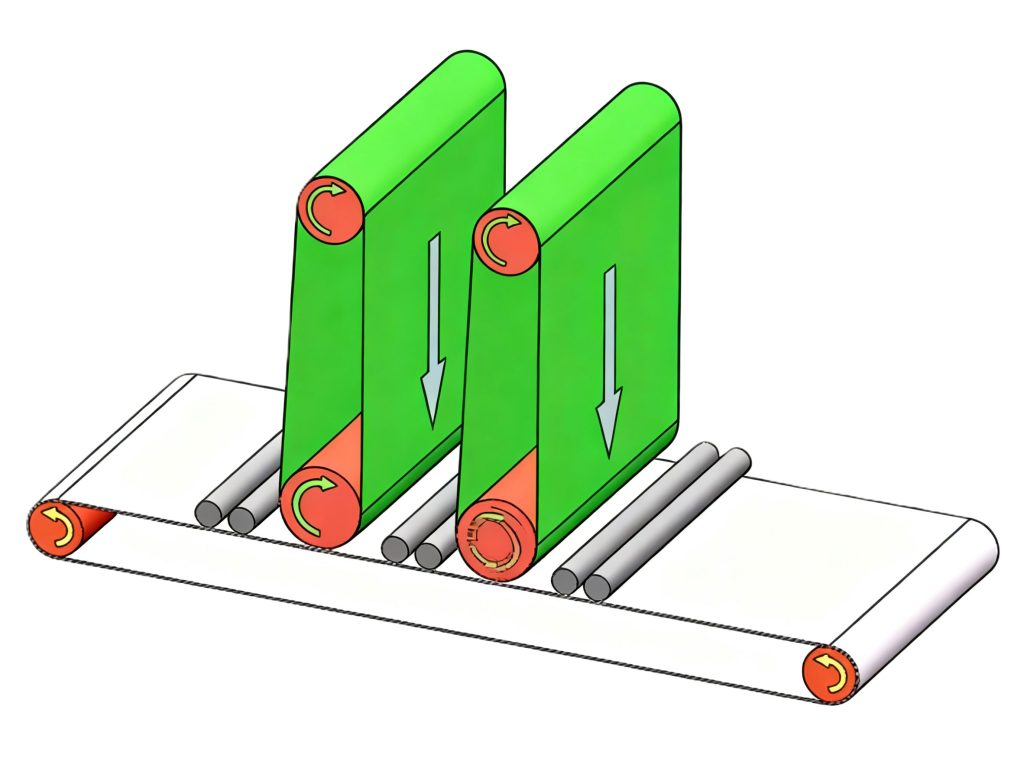

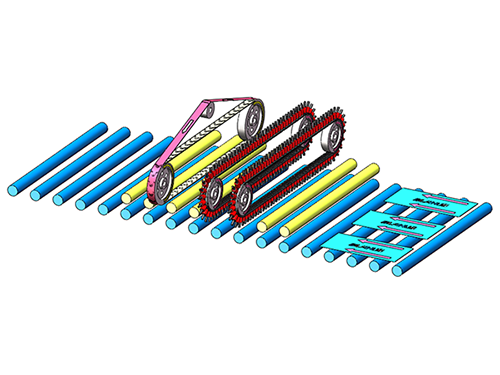

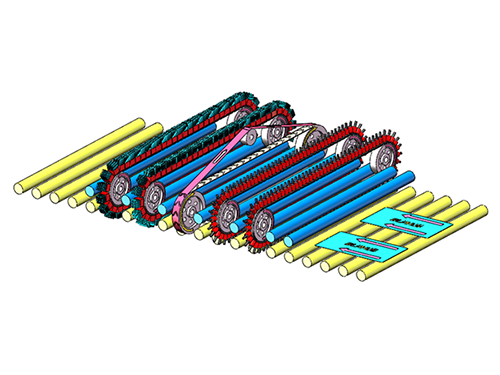

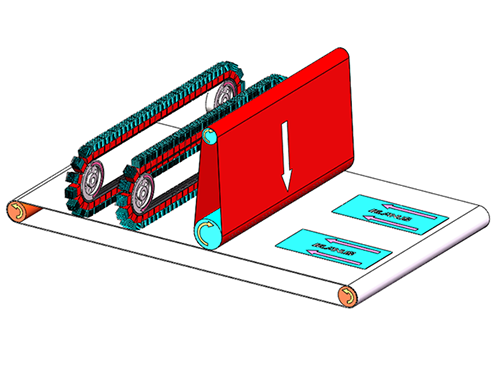

Fully Automatic Deburring and Chamfering Equipment

Equipment functions: For various cut workpieces, it realizes surface pre-grinding, wire drawing, polishing, scratch removal, deburring, and chamfering/edge blunting.

- Equipment processing width: 800mm, 1000mm, 1350mm, 1600mm.

- Equipment processing thickness: 0.5-100mm.

- Conveying and feeding speed: 0.5-6m/min (frequency conversion adjustable).

- Four-column synchronous lifting, with independent lifting of the roller brush station, controlled by lifting servos, and an accuracy of 0.01mm.

- The entire machine's numerical control PLC touchscreen is used to adjust processing parameters.

- Permanent magnetic adsorption conveying and feeding (applicable to carbon steel workpieces. Workpiece size ≥ 10mm × 10mm)

- Vacuum negative pressure adsorption conveying and feeding (applicable to stainless steel plates, copper plates, aluminum plates and other materials that are not magnetically adsorbable. Workpiece size ≥ 50mm × 50mm)

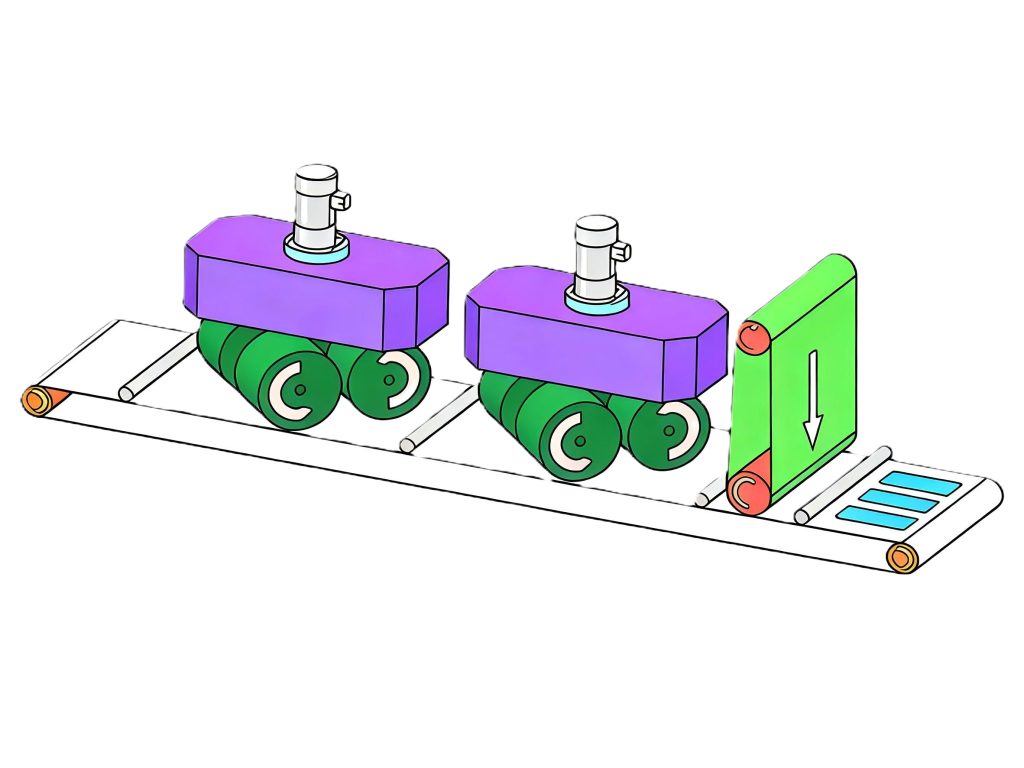

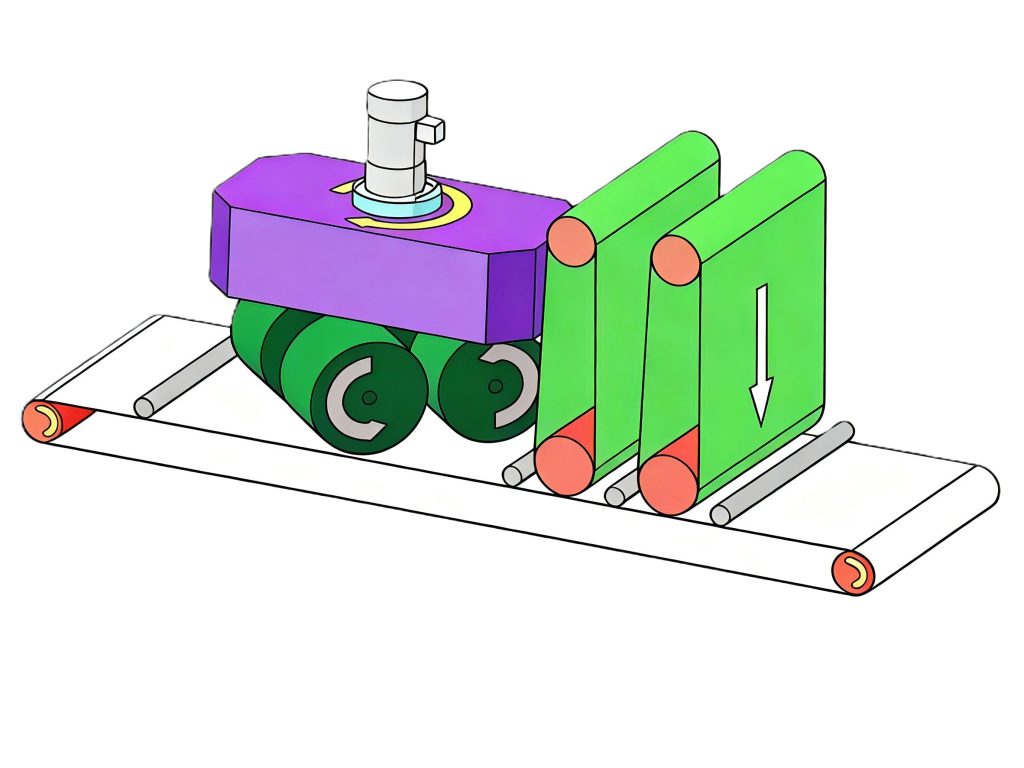

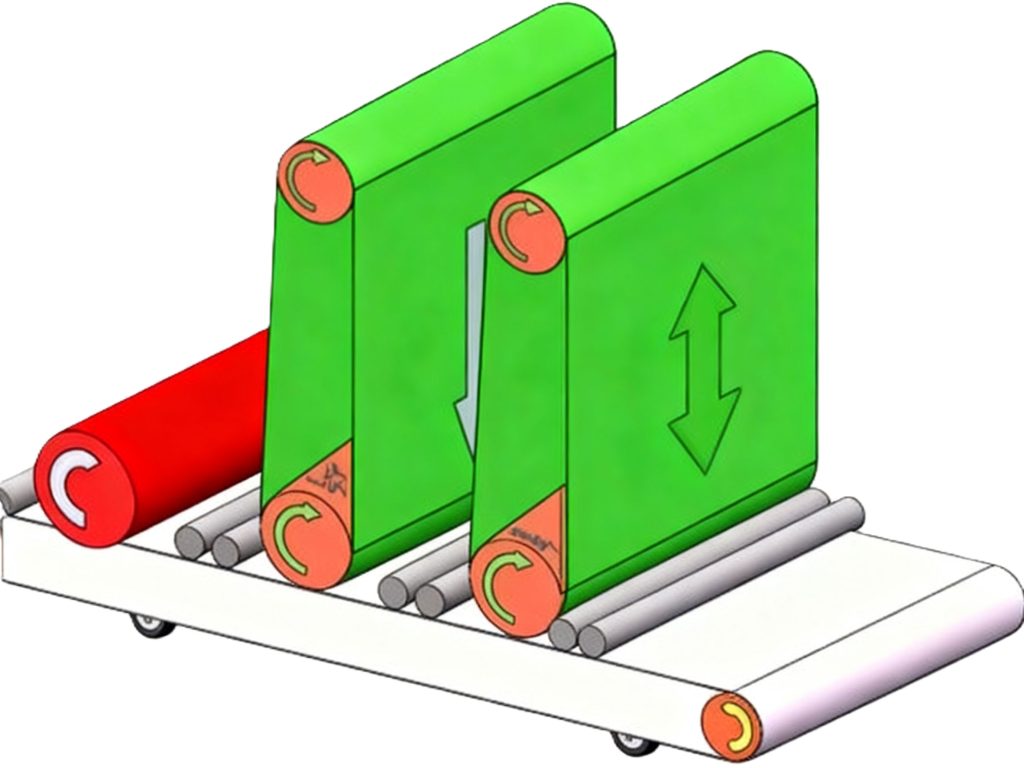

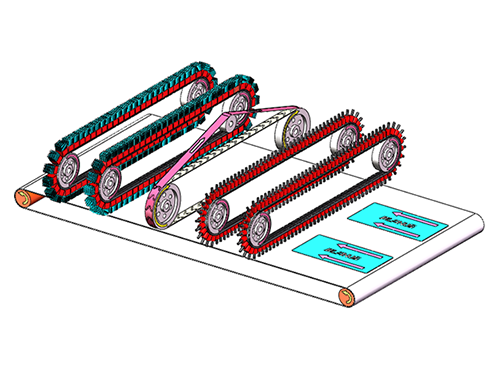

Fully Automatic Polishing and Brushing Equipment

For carbon steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, and rubber-plastic materials, the product surface aesthetics and smoothness are enhanced through brushing, precision polishing, scratch removal, longitudinal burr removal, and oxide scale removal

- Equipment Processing Width: 350mm, 650mm, 800mm, 1050mm, 1350mm, 1600mm, 2000mm, 2200mm.

- Equipment Processing Thickness: 1-80mm.

- Abrasive Belt Linear Speed: 18m/s (frequency conversion speed regulation optional).

- Polishing Wheel Linear Speed: 20m/s (frequency conversion speed regulation optional).

- Conveyor Feeding Speed: 2-11m/min (frequency conversion adjustable).

- Four-column synchronous lifting, with digital setting and reading of lifting height (unit: mm)

- A matching automatic paper tape filter is provided to filter grinding dust and supply recycled grinding fluid for grinding, realizing environmentally friendly production.

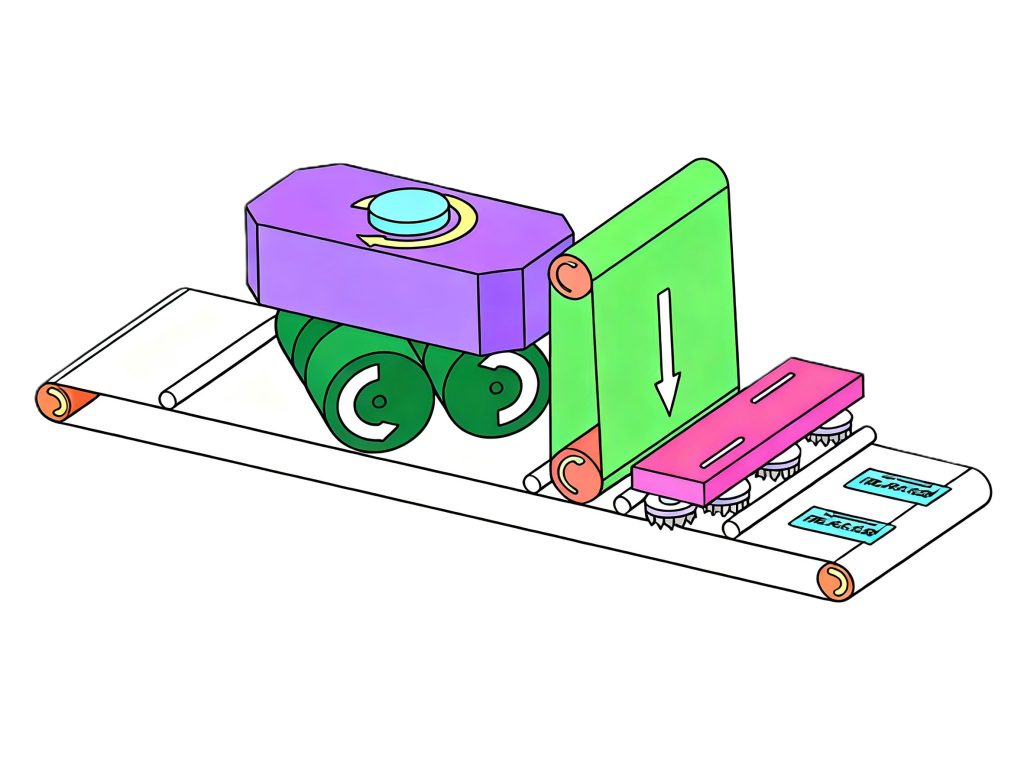

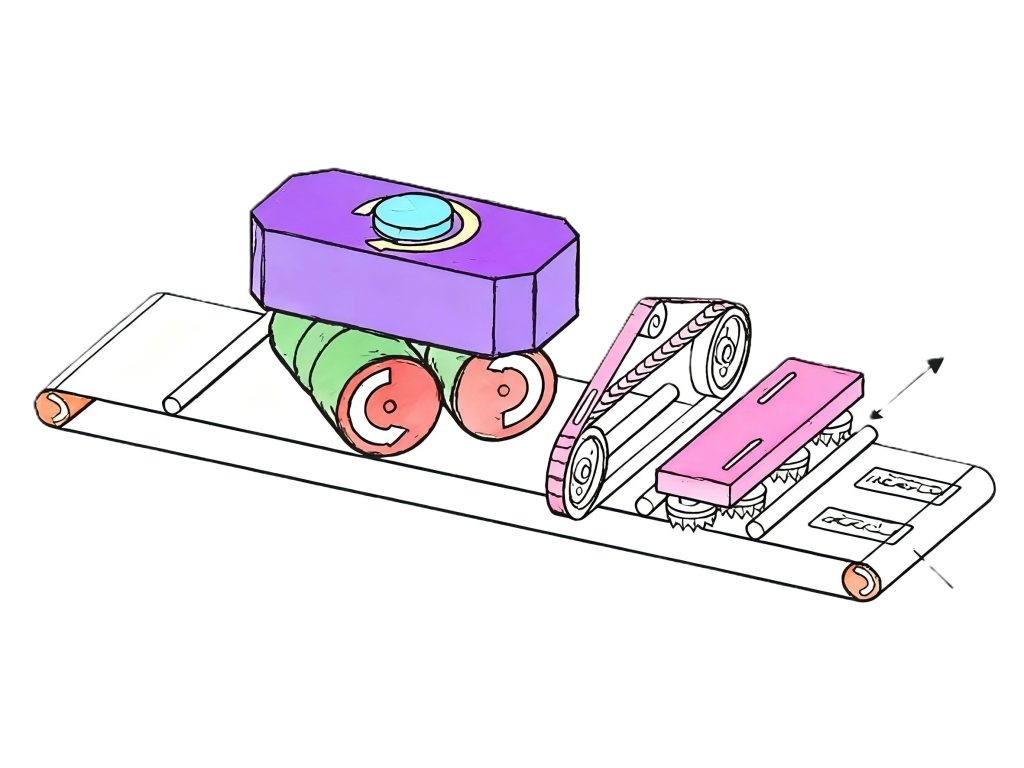

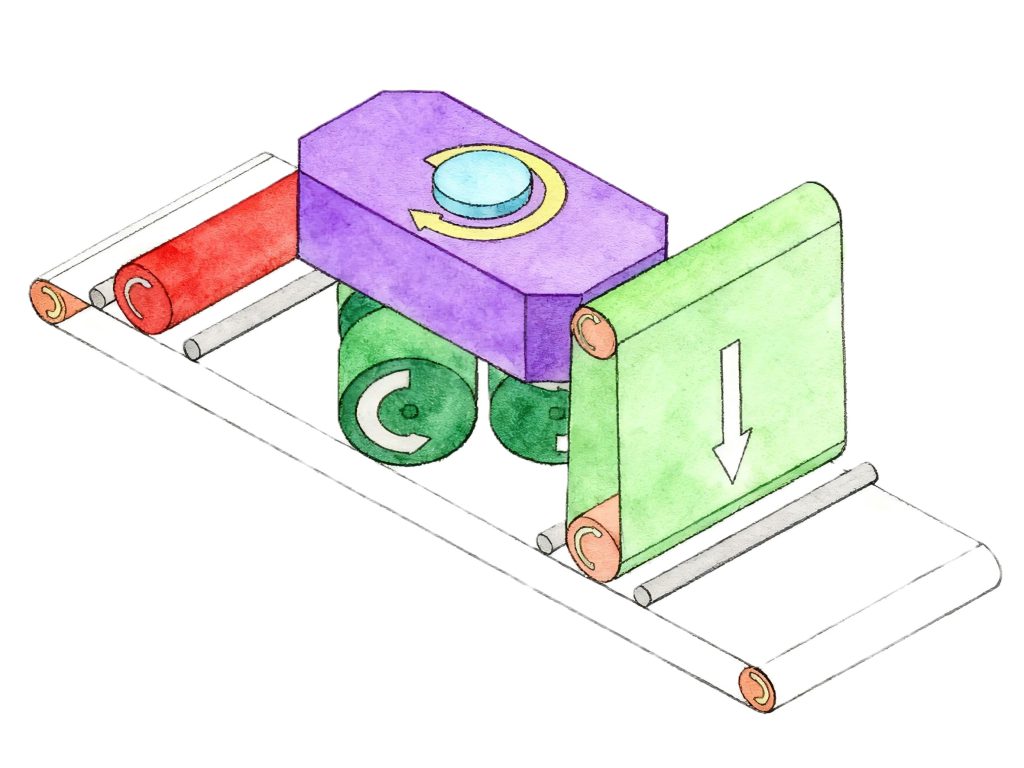

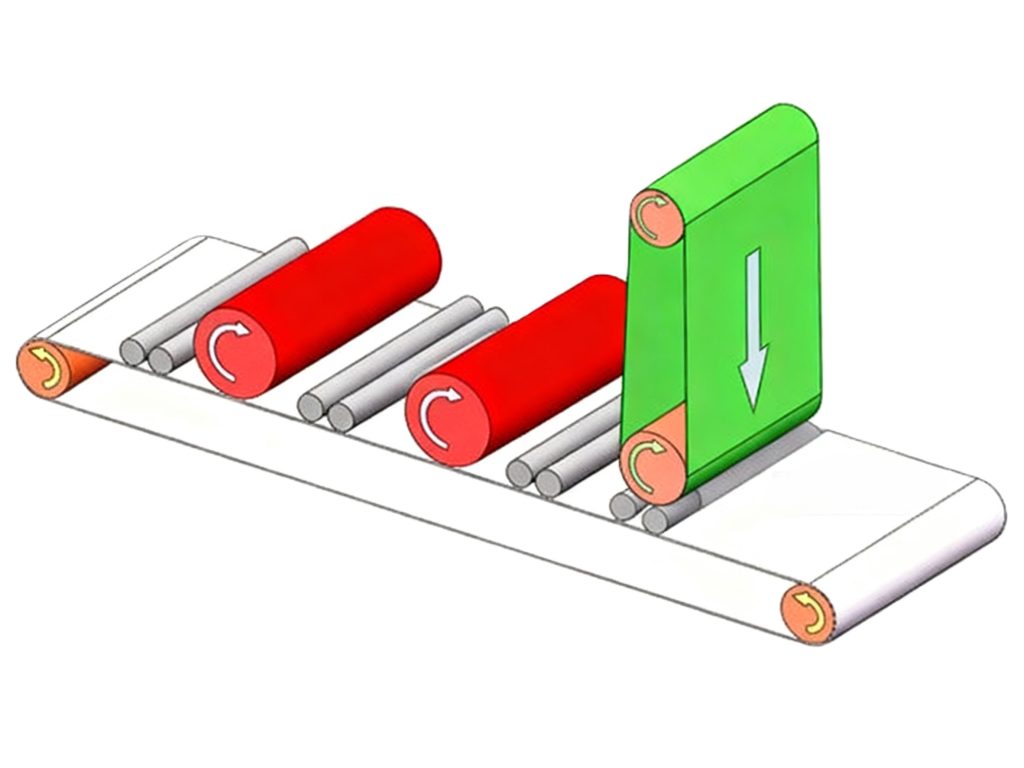

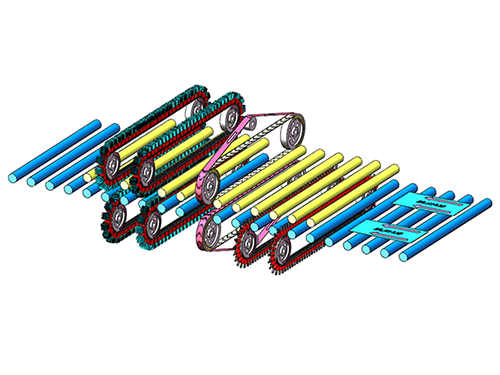

Slag-Removing and Heavy-Duty Slag Removal Machine

The series of equipment includes multi-station combined grinding machines (single-sided / double-sided) for wide-width / narrow-band abrasive belts and abrasive strips. It can achieve all-round removal of slag and burrs generated from metal plate cutting, stamping and machining in a single pass.

- Processing width of the equipment: 800mm, 1000mm, 1350mm, 1600mm, 2000mm, 2200mm, 2500mm

- Processing thickness of the equipment: 1-100mm

- Conveyor belt + rubber press roller pinch feeding (applicable to ordinary workpieces. Workpiece length > 150mm)

- Strong permanent magnet adsorption conveying and feeding (applicable to carbon steel workpieces. Workpiece size > 30mm x 30mm)

- Vacuum negative pressure adsorption conveying and feeding (applicable to stainless steel plates, copper plates, aluminum plates and other materials that are not magnetically adsorbable. Workpiece size > 50mm x 50mm) Rubber roller + rubber roller pinch feeding

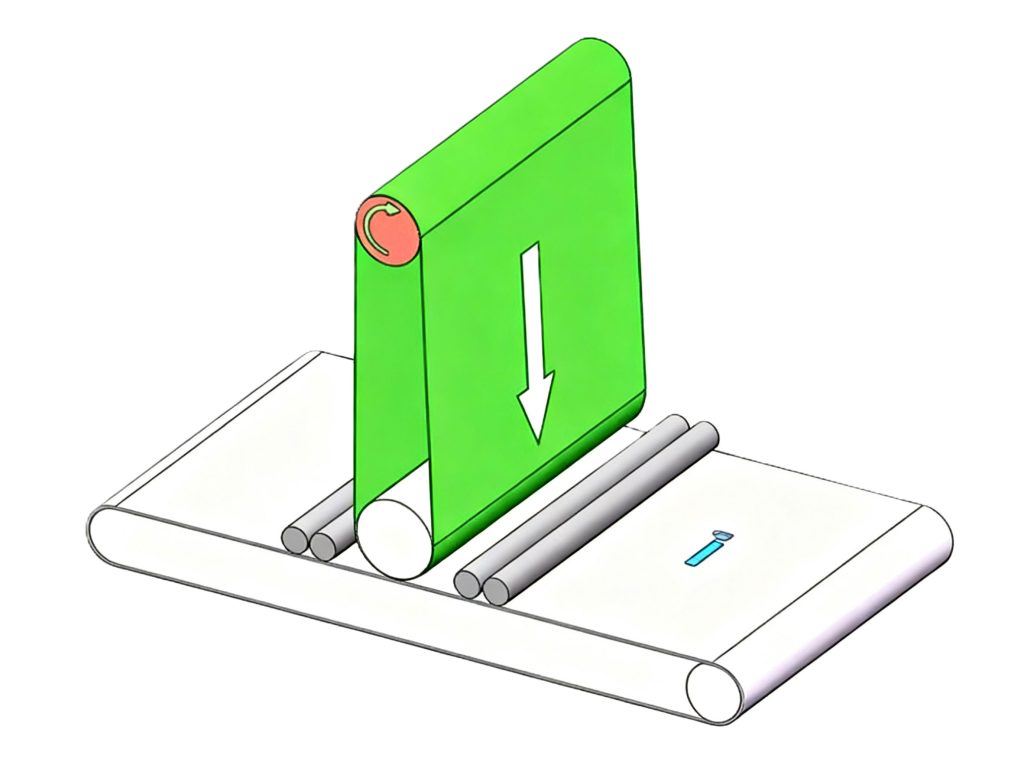

Manual Deburring and Chamfering Equipment

It is composed of a workbench and a mechanical polishing arm, and is suitable for surface polishing, slag removal, deburring and other treatments of small batches of metal plates.

- Size of vacuum adsorption platform: 420*280mm

- Workpiece on upper platform: 1000*750mm

- Workpiece not on upper platform: 1200*1200mm

- Cantilever working range: 1200*360°

- Processing workpiece thickness range: 0.1-150mm

- Grinding head power: 0.75kw

- Grinding head speed regulation: 500-1400r/min

- Grinding heads: 2

- Dust suction capacity: 1000m³/h

- Total power: 3.86kw

- Volume: 1250*750*1500mm

Apllication Industry

Cars

Electronics

Medical

Aerospace

Construction

windows

Engineering machinery

Farm Machine

Rail Traffic

truck

Fabrication Shop

New Energy

Light Pole

Ship

petrochemical

Home furniture

Stamping and welding of stainless steel cabinets, metal wardrobe frames, metal brackets for lamps, anti-theft doors/guardrails

Why choose SMS Machinery?

We not only provide high-quality deburring equipment, but also offer comprehensive solutions and service support.

- Based on the characteristics of the customer's workpieces and their production requirements, we provide tailor-made deburring solutions to ensure the optimal processing effect.

- We provide comprehensive services including installation and commissioning, operation training, and regular maintenance, and offer 24-hour response to customers' technical support needs.

- We provide software upgrade services for the equipment that has been sold, ensuring that customers' equipment always maintains leading technical standards and processing capabilities.

- From equipment selection to production process optimization, we help customers reduce labor costs, improve production efficiency, and maximize return on investment.