Project Overview:

Machine details

- Dual Servo Pump CNC tandem press brake.

- Modle: PPTK -2 *(400tons/3000mm).

- 2*10 Axis ( Y1,Y2,X,R,Z1,Z2,S,K,J+V).

- Italy Esautomotion S875W controller.

- Automatic Adjustable V opening dies (Min.20mm -Max.160mm).

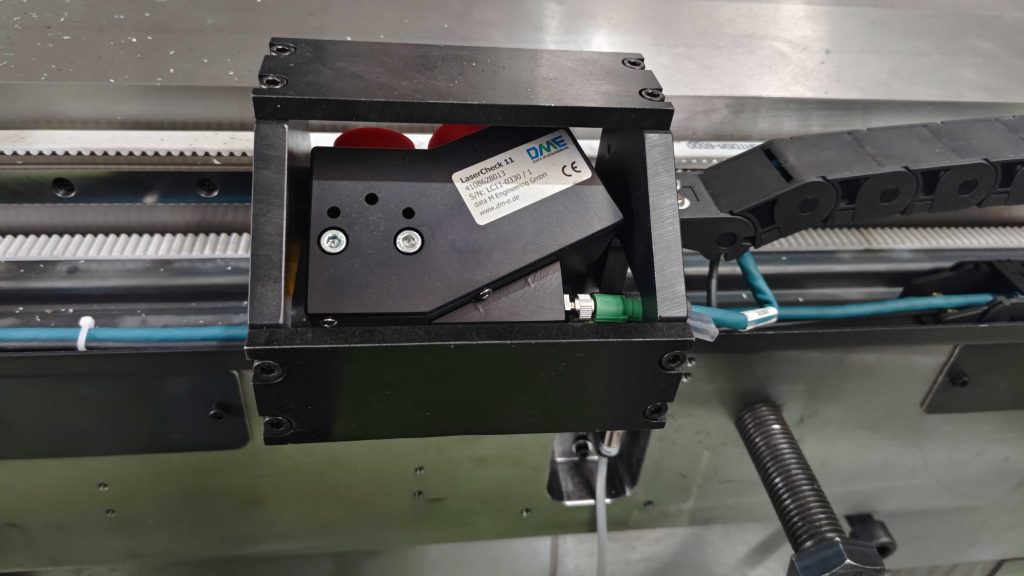

- German Data M Engineering GmbH laser angle check 11.

- Automatic sheet metal followers.

- Servo Pump Control.

About the customer

The customer is dedicated to the manufacture and distribution of steel products and has served customers in Brazil and abroad for over 70 years. The company offers industrial and agricultural parts and components, steel sheets, processing, steelmaking, construction and paving equipment, engineering and transmission chains, conveyor systems, elevators, and conveyors.

- Steel plates (ASTM A-36, SAE 1010/1020/1045, etc.)

- Engineering chains and sprockets.

- Components for agricultural machinery such as planters, harvesters, and sprayers.

- Construction and paving equipment such as rollers and pavers.

- Special machined and forged parts for tractors, graders, and loaders.

- Industrial conveyor systems and tracks.

Machinery Mainly Features:

Part.1-What is a Tandem Press Brake Machine?

The Dual-machine bending machine is composed of two independent CNC bending machines with the same functions connected by a centralized synchronous control system. This structure can be used as two independent bending machines according to needs, or it can be "combined into one" to work synchronously to complete the bending task of extra-long or extra-heavy workpieces.

The core of this design lies in its synchronous control technology, which ensures that the sliders of the two machines can maintain millisecond-level precise synchronization during movement, whether rising, falling, bending or resetting.

Working principle of dual-machine linkage:

- Preparation and positioning: The operator places the extra-long sheet flat on the work tables of the two machines. The backgauge system of each machine will independently or synchronously position the sheet precisely to the specified position.

- Synchronous descent: When the bending program is started, the central control system sends instructions to both machines simultaneously. The hydraulic systems of the two machines are precisely controlled, driving their respective slides and upper molds to descend synchronously at the same speed and path.

- Synergistic Bending: During the bending process, the upper and lower dies of two machines simultaneously apply pressure to the sheet. Due to the synchronized movement of the sliders, the sheet is evenly stressed along the entire bending line, avoiding deformation caused by gravity sagging or uneven force.

- Synchronous reset: After the bending is completed, the control system will synchronize the two machines again, so that their slides rise at the same time, safely complete the reset, and prepare for the next bending task.

The main advantages of dual-machine linkage:

- Processing of extra-long workpieces: This is the core advantage. The workbench length of a single bending machine is limited, but the linkage of two machines can double the effective bending length, easily handling 5-meter, 8-meter or even longer plates, such as utility poles, light poles or large building structures.

- Double the tonnage, upgrade the capacity: The two machines work together, and the total tonnage is added, making it easy to bend extra-thick or extra-hard plates that cannot be handled by a single machine.

- High precision and high consistency: Advanced synchronous control technology ensures high consistency of angles and dimensions throughout the entire bending process, greatly improving product qualification rate and quality.

- Flexibility and high utilization: When there is no need to process extra-long workpieces, the two machines can be used as independent stand-alone machines, each performing its own production task. This flexibility ensures efficient utilization of the equipment and does not waste production capacity by processing only small workpieces.

- Easy to operate: Although they are two machines, the operating interface is unified, and the programming and operation are similar to those of a single machine, which reduces the learning difficulty for the operator.

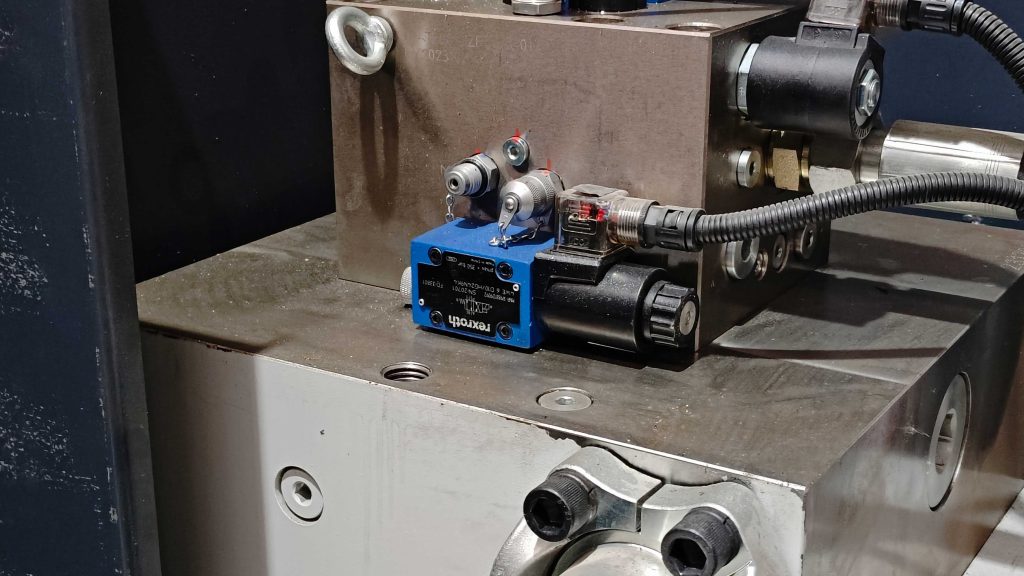

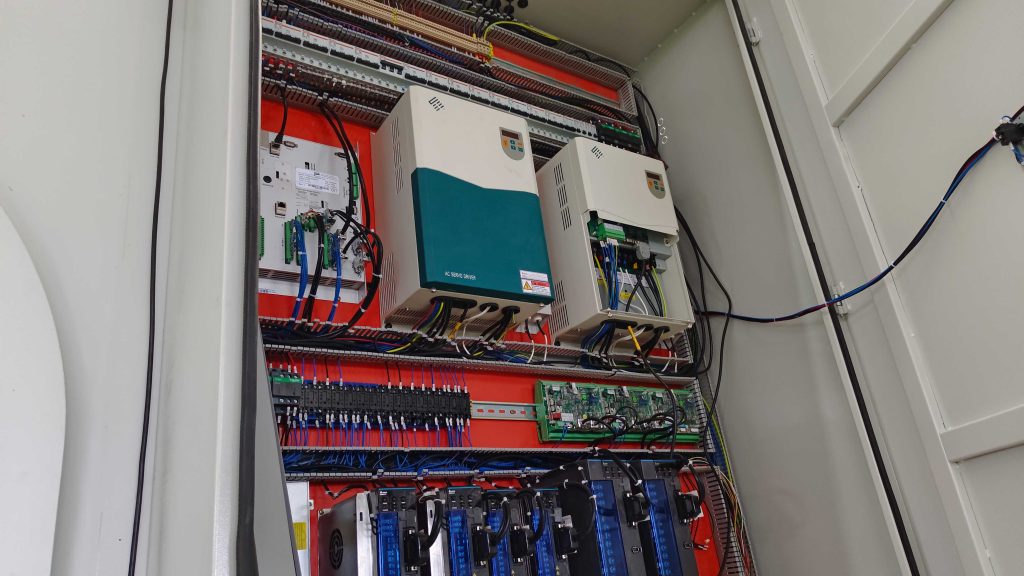

Part.2-Servo Pump Control Hydraulic System

The press brake pump control system is an advanced drive and control technology that precisely controls the movement of the press brake's slide by adjusting the speed of the hydraulic pump in real time. Compared to traditional hydraulic press brakes, the pump control system can significantly improve the machine's efficiency, precision, and energy savings.

Know moreWorking principle of dual-machine linkage:

- Variable frequency or servo drive: The core of the pump control system is the servo motor or variable frequency motor, which directly drives the hydraulic pump.

- Closed-loop control: The system monitors the position and force of the slider in real time through position sensors, pressure sensors, etc., and feeds the data back to the CNC system (CNC).

- Oil supply on demand: The CNC system accurately calculates the required oil flow and pressure based on the preset program and real-time feedback data, and controls the servo motor to run at the corresponding speed.

Main Advantages:

- High efficiency and energy saving: This is the most prominent advantage of the pump control system. Since the motor only runs when needed and the speed is adjustable, it can save 30% to 60% of electricity compared to traditional systems, greatly reducing operating costs.

- High-precision control: The pump control system adopts servo closed-loop control, which can achieve micron-level precision of slider position and bending angle, ensuring the consistency and high quality of bent parts.

- High dynamic response: The servo motor has a fast response speed and can quickly change the speed, making the slider's descent, bending, return and other actions more stable and accurate, thereby improving production efficiency.

- Low noise: The motor produces almost no noise when in standby mode or running at low speed, which significantly improves the working environment in the workshop.

- Reduce heat generation: Due to the precise control of oil flow, the throttling loss of oil under high pressure is reduced, the hydraulic oil temperature rise is small, and the service life of hydraulic components and seals is extended.

Part.3-Italy Esaumation VIS-800 Controller (S875W)

With VIS – 800 Esautomotion redefines CNC standards, offering a series of innovations and features that incredibly improve efficiency and productivity during installation on machines and systems. The speed and graphics performance also guarantee an optimal user experience for end users.

Know more

- Intelligent modularity:1 rack only for all models. This allows a significant reduction in warehouse stocks and an exceptional simplification of the connections to the axes and control units to all the other devices installed on the machines.

- 100% Digital:the VIS – S800 series was born with a full digital concept thanks to the Ethercat communication protocol.

- 100% Wifi Connectable:The VIS – 800 CNCs are designed for the Industry 4.0 logics: they can all be connected to the internet, allowing an absolute level of integration with the other systems and management software installed inside the company.

- New GlassOnly screens, 100% Full Touch:Developed on Esautomotion specifications,its are all equipped with a chipset to support high-level graphics performance.

- Advanced HMI graphic tools:Possibility to develop complex and 3D interfaces, simplifying user interaction.

- Turn-key power:All VIS – 800 CNCs are software-bundled and immediately operational, with significant savings in terms of time and costs.

- Maximum versatility:VIS – 800 CNCs are adaptable to all possible applications: sheet metal cutting and bending, marble, wood cutting, general purposes.

- Remote tele-assistance for all models:Fast Service Esautomotion and Industry 4.0 fully combined thanks to the permanent connection with the customer and the end user.

Part.4-Automatic Adjustable V Opening Dies (V20mm-V160mm)

The adjustable opening die of the press brake is an innovative bending tool that allows the operator to adapt to different sheet thicknesses or achieve different bending angles by adjusting the width of the V-groove opening of the die without changing the die. This die greatly improves the flexibility and production efficiency of the bending operation.

Know more

Main Advantages:

- Hydraulic adjustment: The V-groove opening is quickly and automatically adjusted by pushing or pulling the die side plates through hydraulic cylinders. This is usually integrated with the CNC system, allowing the opening size to be set directly in the bending program.

- Efficient and flexible: The biggest advantage is that it saves time in frequent mold changes, especially when processing workpieces of various thicknesses or various bending radii, it can achieve rapid switching, greatly improving production efficiency.

- Reduce costs: One set of adjustable molds can replace multiple sets of fixed opening molds, reducing mold procurement costs and storage space.

- Improved precision: The precise adjustable mechanism can ensure the accuracy of the V-groove opening size, and combined with the CNC system, more precise bending angle control can be achieved.

- Easy to operate: Whether manual or automatic adjustment, the operation is much simpler than replacing heavy traditional molds, reducing labor intensity.

- Reduced waste: The ability to precisely control the bending process reduces scrapped workpieces due to improper tooling selection.

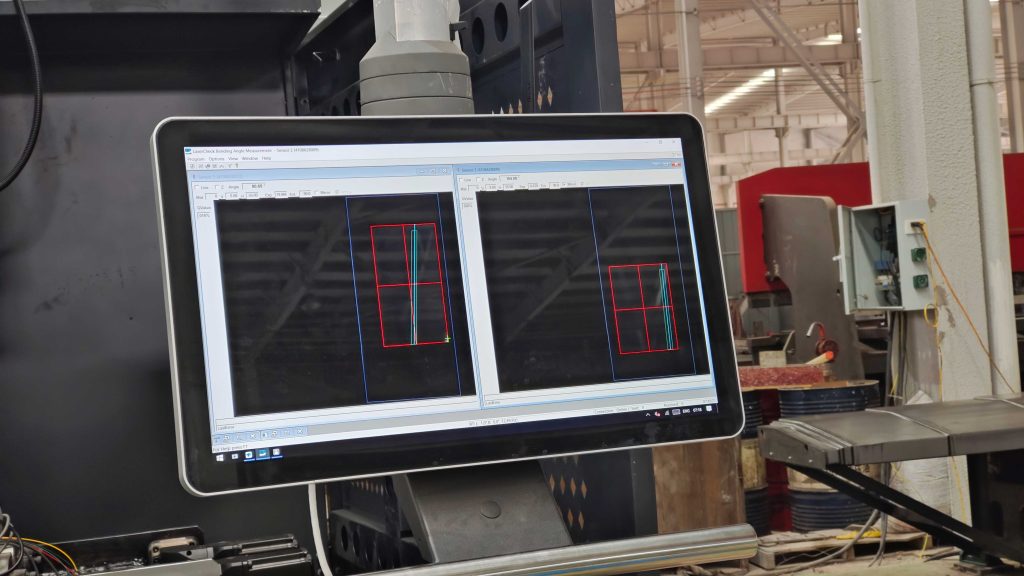

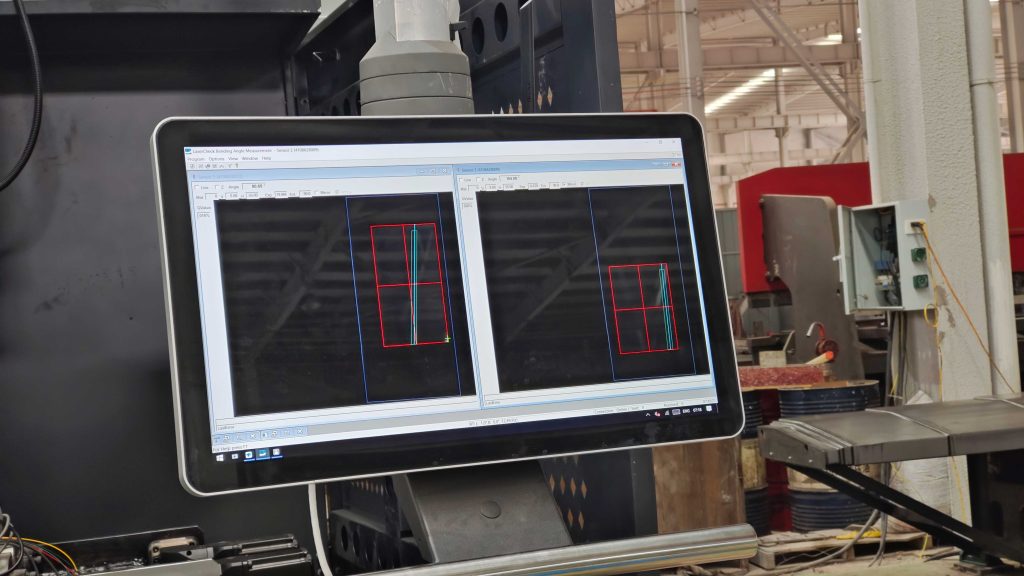

Part.5-Bending Angle Check with Laser

The laser angle detection system for press brakes is an advanced measurement technology that uses laser sensors to monitor and correct the angles during the bending process in real time to ensure the accuracy of the workpiece. This technology greatly improves the quality consistency and production efficiency of bent parts, especially when processing high-demand materials or materials with significant spring back effects.

Know more

Main Advantages:

- Extremely high precision: Able to achieve bending angle accuracy of ±0.1° or even higher, far exceeding the level of manual inspection and manual adjustment, ensuring consistent product quality.

- Compensation for spring back: For materials with significant spring back effect such as stainless steel and high-strength steel, the system can automatically compensate without the operator having to rely on experience to repeatedly try to fold.

- Improve production efficiency: Automated measurement and correction eliminates the need for trial folding and manual measurement, significantly shortening the processing time of a single workpiece.

- Reduce material waste: Due to the high bending precision, the scrapping of workpieces due to inaccurate angles is reduced.

- Reduced operator dependence: The system has a high degree of automation, which reduces dependence on operator experience and skills, allowing new employees to quickly get started.

Part.6-Automatic Sheet Metal Support

A press brake sheet metal support device, also commonly known as a follower support device or follower feeder, is an automated auxiliary device installed at the front end of a CNC press brake. Its main function is to provide synchronous and continuous support from below when bending long plates or large workpieces, preventing the plates from sagging or deforming due to their own weight during the bending process.

Know more

Why use a sheet metal support device?

- Affecting bending accuracy: The sagging sheet will cause the bending line to deviate from the preset position, resulting in inaccurate bending angles and even waste.

- Increased operational difficulty and labor intensity: Operators need to lift the panels with their hands or other tools, which is laborious and difficult to maintain stability.

- There is a safety hazard: The sagging of large-sized plates may cause injury to operators.

- Reduced production efficiency: Additional manpower or time is required to deal with the plate sagging problem, affecting overall production efficiency

How it works?

- Initial positioning: The operator places the sheet to be bent on the support arm of the pulling device.

- Synchronous movement: When the slider of the bending machine moves downward to start bending, the support arm of the device will be driven by a servo motor or hydraulic system to maintain a synchronous rising speed and angle with the slider.

- Continuous support: Throughout the bending process, the support arms remain in close contact with the bottom of the sheet, providing constant support and ensuring the sheet remains horizontal at all times, unaffected by gravity.

- Bending completed: After the bending is completed, the support arm will fall to the initial position synchronously with the slider, waiting for the next bending cycle.

Main Advantages:

- Significantly improve bending accuracy: effectively eliminate sheet metal sagging and ensure the accuracy of bending angles and dimensions.

- Reduce labor intensity: No manual lifting is required, and one operator can easily complete the bending of large-sized plates, greatly reducing physical exertion.

- Improve production efficiency: simplify operation process, reduce auxiliary time and speed up production rhythm.

- Improved operational safety: Reduced accidents caused by sagging or loss of control of the plate.

- Expand processing capacity: Enable the bending machine to stably process longer, wider and heavier plates.

Part.7-Europe Promecam Clamping

Know more

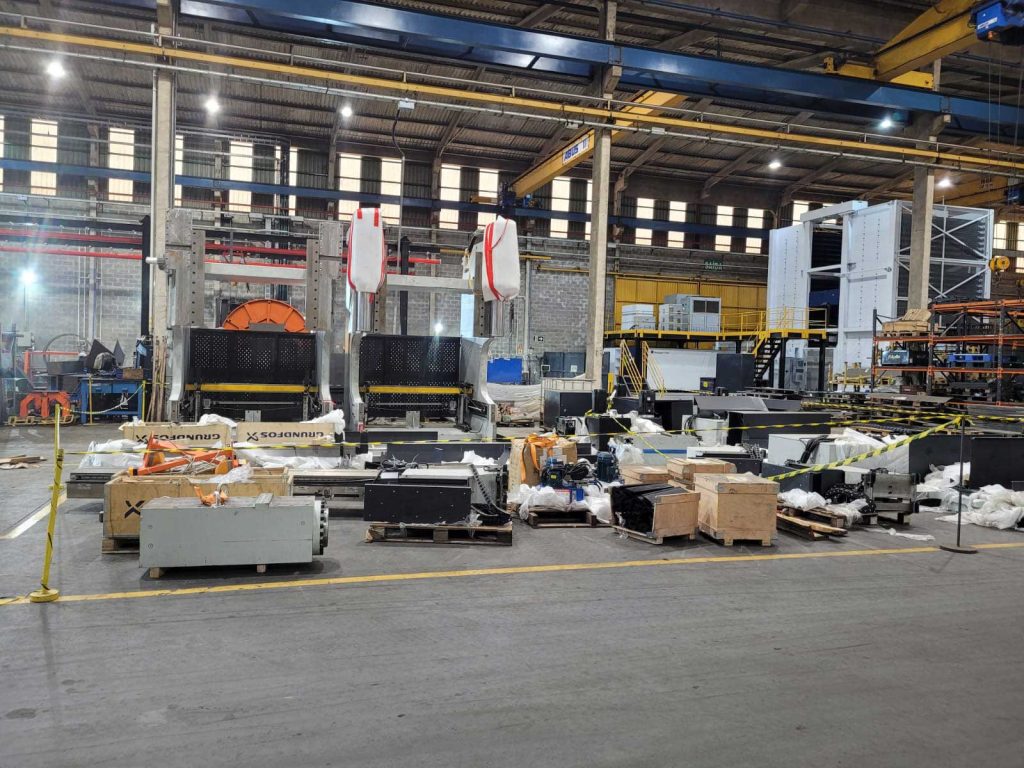

time Line

-15th,Sep,2023-Leading Fallgatter customers to visit SMS factory

-17th,Oct,2023-The two company signed a contract and started production.

-15th,Nov,2023-The main frame is cut.

-20th,Nov,2023-Main structure welding completed

-30th,Nov,2023-Automatic adjustable v opening dies start processing.

-7th,Jan,2024-The main frame has been assembled.

20th,Jan,2024-Assembly completed and commissioning started

20th,Feb,2024-The customer came from Brazil to the SMS factory in China to inspect the machine.

9th,May,2024-Packaging and Shipping.

20th,Jul,2024-The machine arrived at the customer's factory in Brazil.

-24th,Aug,2024 to 10th,Sep,2024-SMS engineers went to the Brazilian factory to install equipment

Key wards:press brake;cnc press brake;hydraulic press brake;cnc press brake machine;press brake machine;press brake back gauge;press brake bending machine;press brake brands