Automatic Adjustable V opening dies

The fully automatic opening-adjustable lower die for bending machines is an advanced die device used in bending machines. It can automatically adjust the V-groove opening size of the lower die according to requirements such as different sheet thicknesses and bending radii, thereby improving production efficiency and processing accuracy.

Browse MoreRequest a quoteWhat is a fully automatic open adjustable mold?

The fully automatic open adjustable mold is a core component of the bending machine. It adopts advanced numerical control technology, which can automatically adjust the opening size and realize the rapid conversion production of various workpieces.

- Fully automatic adjustment, reducing manual intervention.

- Quick mold change, improving equipment utilization.

- High-precision control, ensuring bending quality.

Features of the Fully Automatic Adjustable Mold

Our molds integrate the latest technology and precision manufacturing, bringing you an excellent bending experience.

Browse MoreHigh-speed adjustment

It has a fast response speed, with the opening adjustment time shortened by more than 60%, significantly improving the production rhythm and efficiency.

Precise control

The adjustment accuracy can reach ±0.01mm, ensuring precise and consistent bending angles and improving the stability of product quality.

Intelligent compatibility

It is compatible with bending machines of multiple brands and supports seamless integration with digital control and automated production lines.

Durable Design

It is made of high-strength alloy materials with surface hardening treatment, extending the service life by more than 30%.

Wide-range adjustment

The opening has a wide adjustment range, which can meet the bending needs of workpieces with different thicknesses and materials

Data Recording

It is equipped with a built-in intelligent recording system that can track the usage status and adjustment parameters of the mold

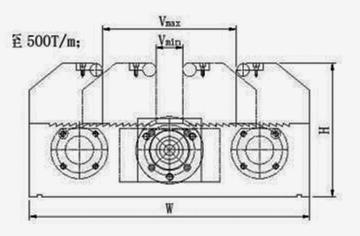

Main Structure

Automatic Adjustable v opening dies

10 seconds to adjust the opening degree from 0 to 100 mm.

- High-quality mold steel, overall heat treatment process, and tempering to eliminate internal stress

- Key parts adopt laser quenching, which ensures the high strength and long service life of the mold.

- It can be installed on bending machines of all brands, and the mold control system is compatible with the bending machine controller system

- High-quality branded servo motors, high-precision reducers, and precision ball screws are adopted to ensure the fast and accurate adjustment of the mold opening size.

- Dust-proof cloth is provided to protect the mold from dust and debris, thus preventing any impact on the mold's normal operation.

Upper Die Base / Lower Die Base

Basic Support Module: Serves as the load-bearing and installation foundation

- It is made of high-strength alloy steel (e.g., 42CrMo), featuring extremely high rigidity and deformation resistance.

- The upper die base is used to fix the cutting edge of the upper die.

- The lower die base integrates an opening adjustment mechanism.

Die Core / Cutting Edge

Opening Adjustment Drive Module: Enables changes in opening size

- The working components that come into direct contact with the plate are made of high-hardness tool steel (e.g., Cr12MoV) through heat treatment, ensuring wear resistance and bending accuracy

- The lower die core is designed as a detachable or slidable structure to match the opening adjustment.

Drive Unit:Servo Motor + Ball Screw

Opening Adjustment Drive Module: Enables changes in opening size

- The servo motor provides precise rotational speed and torque control

- while the ball screw converts rotational motion into linear motion

- enabling high precision (typically up to 0.01 mm) for opening adjustment.

- Hydraulic drive is also used for large-scale molds to provide greater thrust.

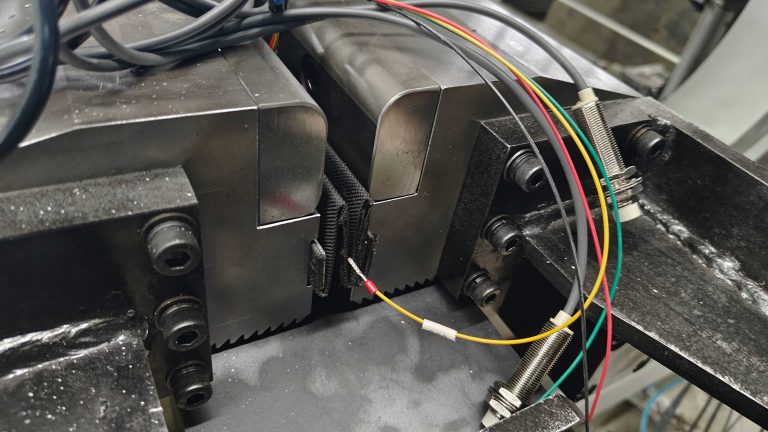

Adjustment Component

Opening Adjustment Drive Module: Enables changes in opening size

- Movable Die Insert, Synchronous Gear / Rack

- The movable die insert is mounted on the lower die base and driven by a lead screw or rack, moving synchronously left and right along the guide rail to change the opening size of the lower die.

- The synchronous gears/racks ensure that the inserts on both sides move at a consistent speed, preventing opening deviation.

Guide Rail

Guiding and Positioning Module: Ensures adjustment accuracy and bending stability.

- Usually linear guides or precision pin-bushing structures, mounted between lower die base and movable inserts to ensure horizontal movement only, no vertical/front-back play.

Positioning Detection Unit

Guiding and Positioning Module: Ensures adjustment accuracy and bending stability.

- It integrates a linear scale or encoder to detect the position of the movable insert in real time, and feeds the data back to the control system to form a closed-loop control, preventing the accumulation of adjustment errors.

Locking Mechanism

Guiding and Positioning Module: Ensures adjustment accuracy and bending stability.

- After adjustment to the correct position, the movable insert is locked via an electromagnetic lock or hydraulic clamping device to prevent changes in the opening size caused by force application during the bending process.

Control Unit

Automated Control Module: Enables "fully automated" operation

- It is built with a PLC or a dedicated controller, which receives instructions from the bending machine host (such as parameters of sheet thickness and bending angle), automatically calculates the required opening size, and sends driving signals to the servo motor.

Human-Machine Interface (HMI)

Guiding and Positioning Module: Ensures adjustment accuracy and bending stability.

- Through the operation panel of the bending machine, you can manually input the opening size parameters or call the preset process parameter library. Meanwhile, information such as the current opening size and adjustment progress is displayed in real time.