Precision bending, derived from a professional rear gauge system

With 20 years of professional manufacturing experience, we provide a full range of rear gauge solutions from 2-axis to 8-axis, meeting various precision bending needs.

Learn about the systemContact us20 +

Industry Experience

6 +

system Model

10 +

Countries Served

500 +

Equipment Installation

20 Years of Dedication,Forging an Expert in the Bending Machine Industry

Founded in 2005, SMS is a professional CNC press brake manufacturer. Over the past 20 years, we have been committed to providing high-quality and high-precision bending solutions for global customers. Our core competitiveness lies in the continuous innovation of rear gauge technology — ranging from basic 2-axis systems to complex 8-axis systems — which meets the diverse needs for bending precision and efficiency across different industries.

With outstanding R&D capabilities, strict quality control, and comprehensive after-sales service, SMS has become the preferred partner for many well-known global manufacturing enterprises. Our products are widely used in fields such as automotive, aerospace, electronics, and construction.

About SMS

Rear Gauge System: The Core Guarantee for Bending Precision

The rear gauge system is a key component of CNC bending machines, directly affecting bending precision and efficiency. SMS provides a full range of rear gauge solutions from basic to high-end, meeting the needs of different application scenarios.

Core Technology

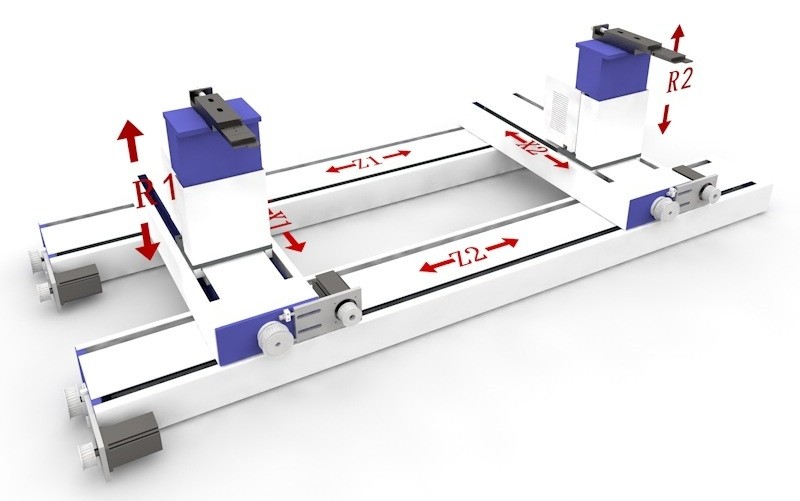

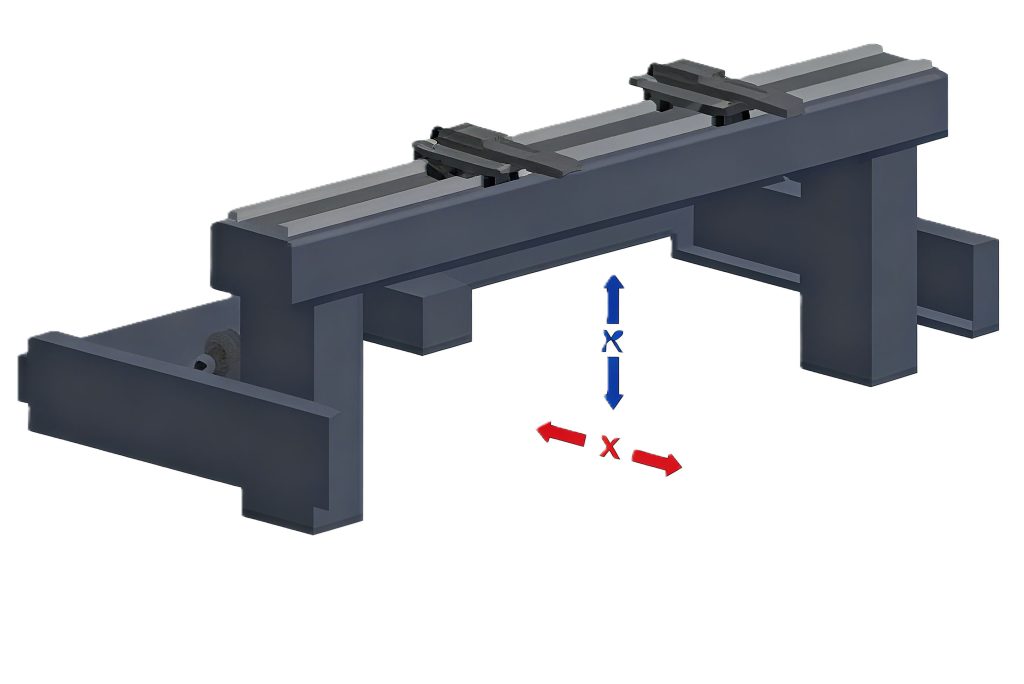

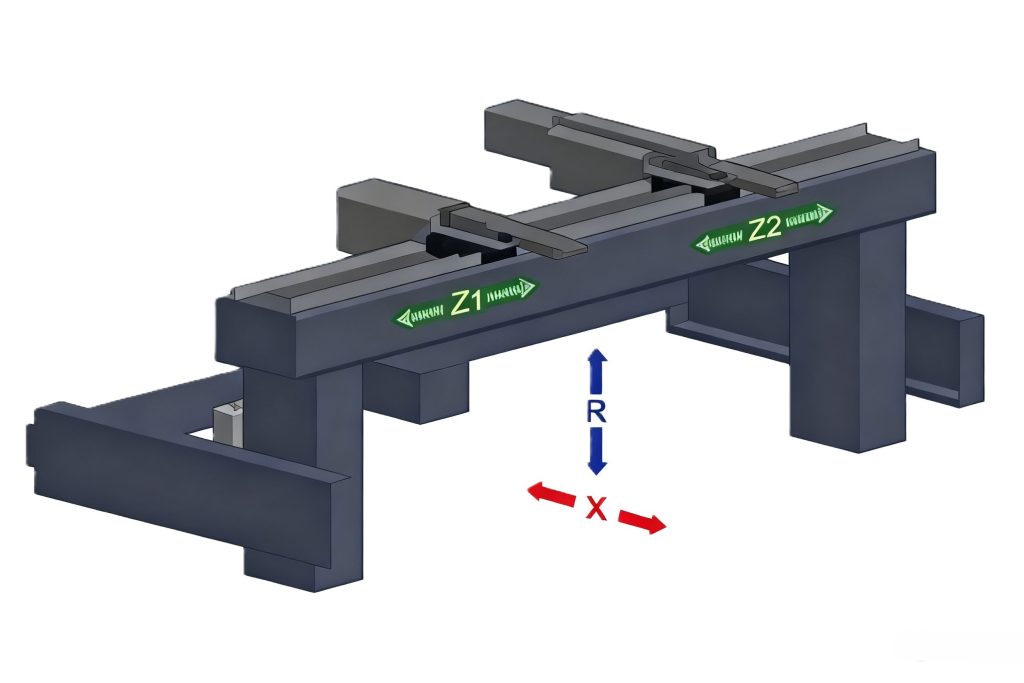

Y,Y1,Y2

Gauge Height Direction Axis

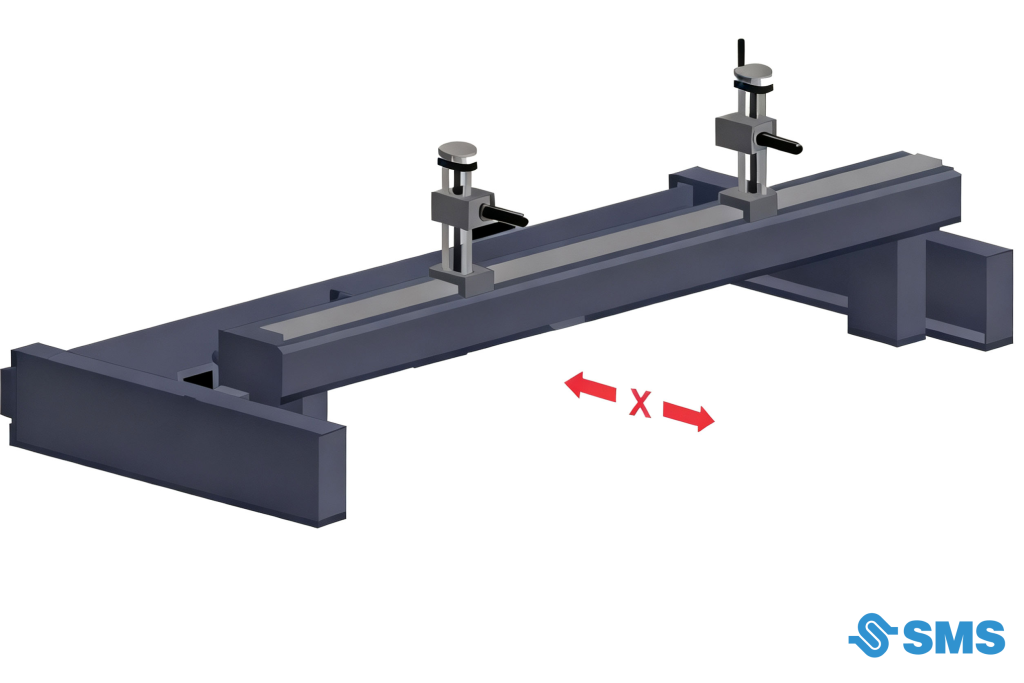

X,X1,X2

Gauge Front-Back Direction Axis

R,R1,R2

Gauge Angle Compensation Axis

Z1,Z2

Gauge Angle Compensation Axis

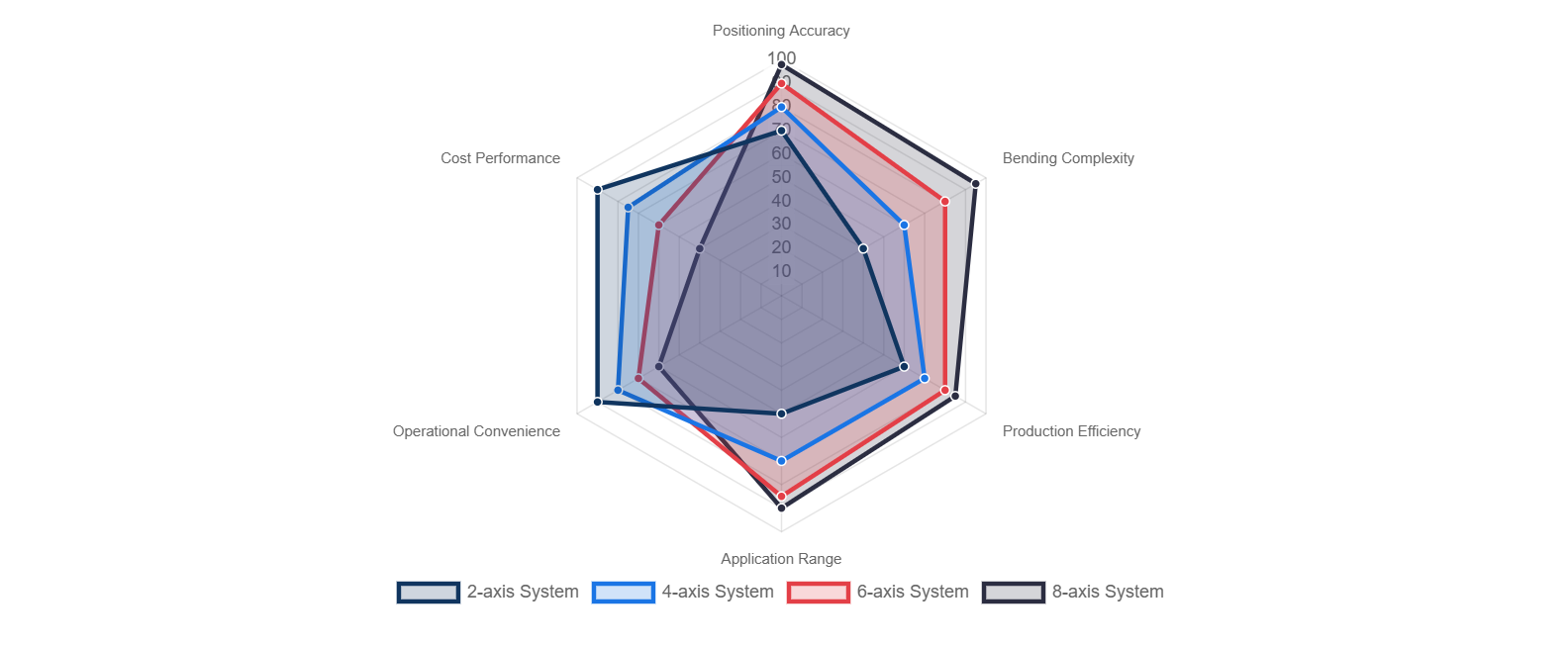

Full Range of Rear Gauge Systems

From basic 2-axis systems to high-end 8-axis systems, SMS provides tailor-made solutions for you to meet different requirements for bending precision and complexity.

System TypeY + X 2 Axis Backgauge Gauge System

- Compact structure and easy maintenance

- High cost-effectiveness, suitable for entry-level applications

- Fast response and precise positioning

- Suitable for mass production of workpieces with simple shapes

Y1, Y2, X, R 4-Axis Rear Gauge System

- Independent control of dual Y-axes, adapting to asymmetric bending

- Angle compensation of the R-axis, improving bending precision

- Capable of handling workpieces with moderate bending complexity

- Flexible programming, supporting multiple bending processes

Y1, Y2, X, R, Z1, Z2 6-Axis Rear Gauge System

- Precise control of Z1/Z2 lateral axes, improving positioning accuracy

- Supports the processing of large workpieces and complex-shaped workpieces

- Automatically compensates for errors caused by material deformation

- High-rigidity structure, ensuring long-term stability

Y1, Y2, X1, X2, R1, R2, Z1, Z2 8-Axis Rear Gauge System

- Independent control of all axes, enabling complex 3D bending

- Micron-level positioning accuracy, meeting ultra-high precision requirements

- Intelligent compensation algorithm, adapting to various material properties

- Supports customized development to meet special process requirements

Common Features of SMS Rear Gauge Systems

No matter which axis count system you choose, you can enjoy the consistent high quality and advanced technology that SMS always provides.

Core AdvantagesUltra-high precision

Fast Response

High Reliability

Intelligent Control

Flexible Adaptation

After-Sales Service

Choose the Rear Gauge System That Fits Your Needs

Whether you need a standard configuration or a customized solution, the professional team at SMS will provide you with recommendations for the most suitable rear gauge system. Fill out the form below, and our technical consultants will contact you as soon as possible.

Contact Us