Professional Laser Machine Solutions

As a professional supplier of fiber laser cutting equipment, SMS Machinery is committed to providing high-precision and high-efficiency laser cutting solutions for the global manufacturing industry, helping enterprises enhance production efficiency and competitiveness

Browse ProductsRequest A quote20 +

Years of Experience

R&D

over 20 senior engineers

Services

Covering over 50 countries

Quality

Strict quality control and testing

About SMS LASER

SMS Machinery is an enterprise specializing in the production and sales of fiber laser cutting equipment, with years of industry experience and accumulation of core technologies.

We have always adhered to technological innovation as the core and customer needs as the orientation, providing high-performance and high-reliability laser cutting solutions for the global manufacturing industry. Our products are sold to more than 50 countries and regions around the world.

Contact usFeatures of SMS Fiber Laser Cutting Machines

Our laser cutting equipment integrates advanced technology and innovative design, providing you with an exceptional cutting experience and production efficiency.

Contact usUltra-high Cutting Speed

Precise Cutting Quality

Low Operating Cost

Stable and Reliable

Wide Adaptability

Intelligent Operation

Main Model

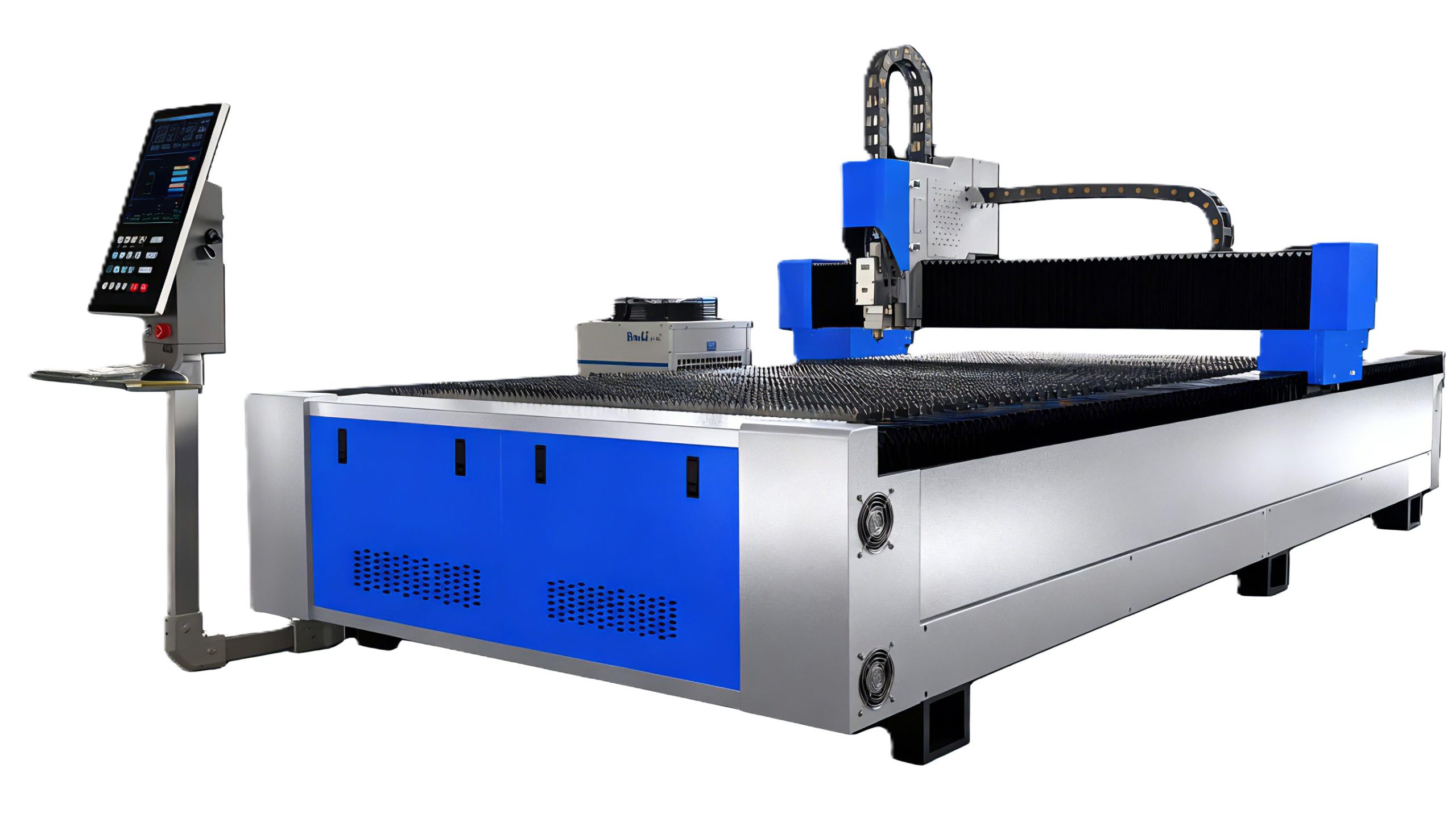

Single table fiber laser cutting machine

- The cost-effective single-table design is suitable for small and medium-batch production, featuring easy operation and a small floor space.

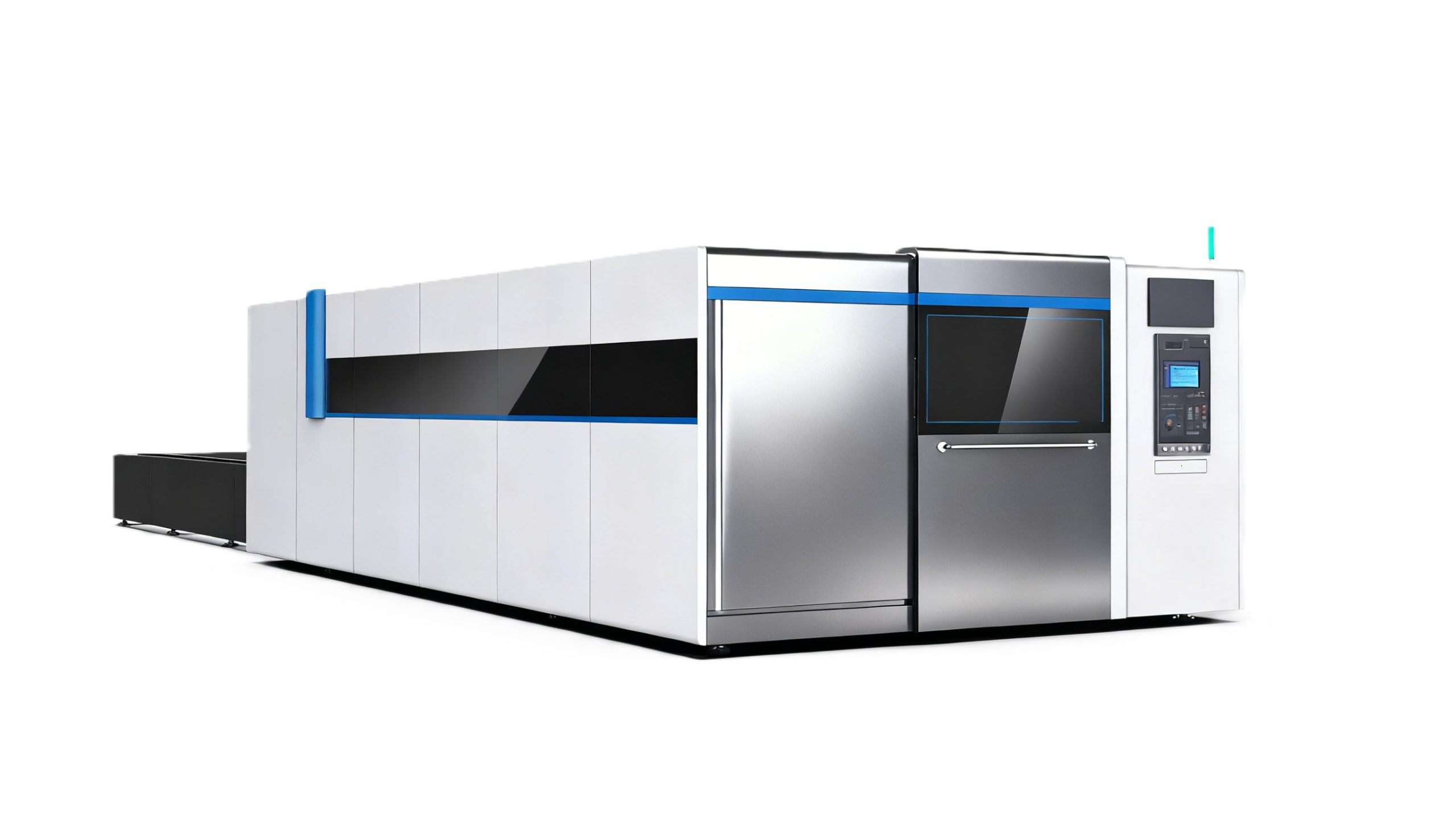

Exchange table fiber laser cutting machine

- Dual worktables enable rapid exchange, allowing cutting and loading/unloading to be carried out simultaneously, which significantly improves equipment utilization.

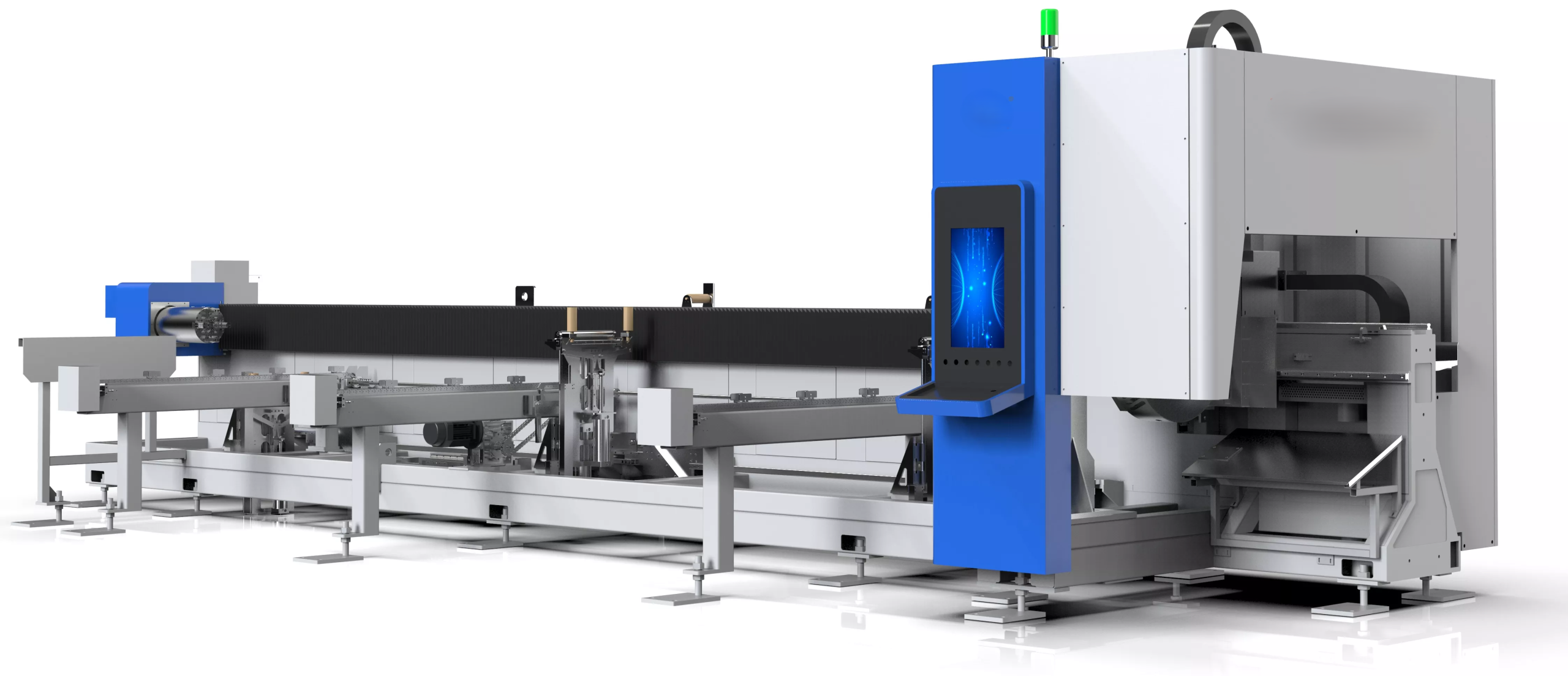

Tube and plate laser cutting machine

- It combines plate and pipe cutting functions in one machine, realizing multi-purpose use and saving equipment investment and floor space.

High Power Ground Rail Laser Cutting Machine

- Designed specifically for cutting large-sized workpieces, it adopts a ground rail structure and is suitable for processing heavy and large plates.

High Power H beam Laser Cutting Machine

- The H-beam laser cutting machine is a special-purpose equipment customized for the steel structure processing industry, supporting the intersecting line cutting, bevel cutting and special-shaped part cutting of various profiled steels such as H-beams, I-beams, channel steels and angle steels.

Semi-Auto Tube Laser Cutting Machine

- Optimized for pipe cutting, it features semi-automatic loading and unloading, making it suitable for the processing of small and medium-batch pipes.

Fully Automatic Tube Laser Cutting Machine

- Full-automatic loading and unloading system, with high-speed and precise cutting, suitable for continuous production of large-batch pipes.

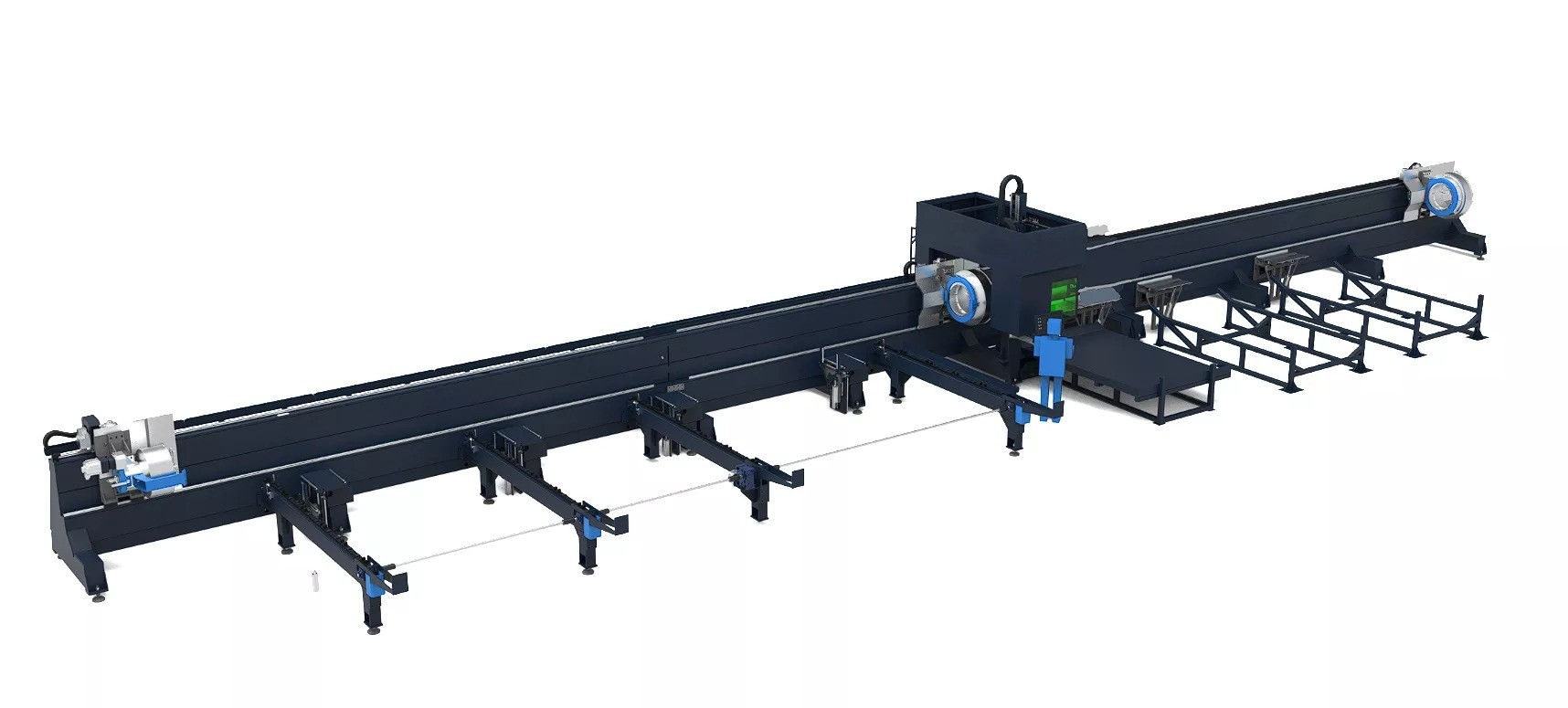

Heavy-Load Three-Chuck Pipe Laser Cutting Machine

- The three-chuck design is specially intended for cutting thick-walled and large-diameter pipes, ensuring cutting stability and precision.

Handheld laser welding

- Using high-power fiber laser and high-speed gantry structure, it can cut flat plates at high speed and high precision

Application Area

SMS laser cutting equipment is widely used in multiple industries and provides efficient cutting solutions for various fields

Request A quoteFabricaiton

Precision cutting and forming, widely used in products such as machine tool enclosures and electrical cabinets.

Car

Precision cutting and forming, widely used in products such as machine tool enclosures and electrical cabinets.

Consturction

Cutting processing of large structural parts and wear-resistant parts, meeting the precision processing requirements of thick plates and high-hardness materials.

Medical Devices

High-precision cutting of medical equipment components, meeting the strict requirements for cleanliness and precision in the medical device industry.

Aerospace

Precision cutting of special materials such as titanium alloys and aluminum alloys, meeting the demand for lightweight and high strength in the aerospace field.

Furniture

Cutting processing of metal furniture frames and decorative parts, supporting the precise realization of complex patterns and shapes.

How to Choose a Laser Cutting Machine?

- Determine the Processing Material and Thickness

- Clarify the Processing Dimensions and Type

- Evaluate the Production Scale and Efficiency Requirements

- Consider the Budget and Long-Term Costs

- Assess the Supplier's Strength and Services

Why Choose SMS Machinery?

We not only provide high-quality laser cutting equipment, but also offer comprehensive solutions and services.

Contact UsCore Technology

It holds multiple patents for core laser cutting technologies, persists in innovation, and maintains a leading technological advantage.

Click HereQuality Control

Strict quality control is implemented throughout the entire production process, and each piece of equipment undergoes a 72-hour continuous operation test before leaving the factory.

Click HereTechnical Training

comprehensive training on equipment operation, programming, maintenance, ensuring that customers can fully utilize the equipment's performance

Click HereFrequently Asked Questions (often abbreviated as FAQ)

Fiber laser cutting machines adopt fiber lasers, with an electro-optical conversion efficiency of over 30%, while the conversion efficiency of CO₂ laser cutting machines is only about 10%. Fiber lasers are more suitable for cutting metal materials, especially high-reflective materials such as copper and aluminum. In terms of operating costs, the electricity fees and maintenance costs of fiber laser cutting machines are much lower than those of CO₂ laser cutting machines. In addition, fiber lasers have a longer service life, which can reach 100,000 hours, while the service life of CO₂ lasers is usually 10,000 to 20,000 hours.

- 1000-2000W is suitable for cutting carbon steel below 3mm and stainless steel below 2mm;

- 3000-4000W can cut carbon steel below 10mm and stainless steel below 5mm;

- 6000W and above can cut carbon steel above 20mm and stainless steel above 10mm.

- Clean the guide rails and lenses daily, and check the coolant level and temperature;

- Inspect the lubrication of guide rails and clean the exhaust vent filter weekly;

- Check the laser head focal length and calibrate the cutting accuracy monthly;

- Examine the optical path system quarterly to ensure stable laser transmission;

- Replace vulnerable parts (such as nozzles and ceramic rings) regularly.

The overall warranty period for SMS laser cutting machines is 1 year, and the warranty period for the core components of the laser is 2 years. Within the warranty period, we provide free parts replacement and repair services (excluding human-induced damage). In addition, we also offer a variety of extended warranty plans, which can be customized according to customer needs to ensure the long-term stable operation of the equipment.

Yes, we provide free operational training services for every customer. After the equipment installation and commissioning are completed, our technical engineers will conduct on-site systematic training for the customer, which lasts 3 to 5 days. The training content includes equipment operation, the use of programming software, daily maintenance, troubleshooting of common faults, and more. In addition, we also provide online training videos and operation manuals to facilitate customers to review and learn at any time.