Precision Intelligent Manufacturing · Efficient Pipe Bending

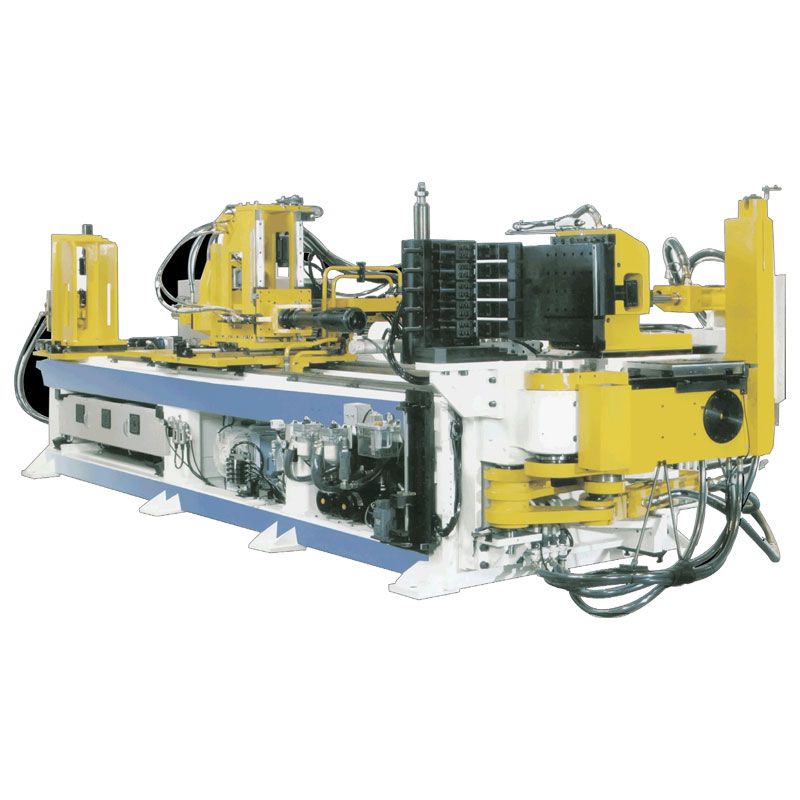

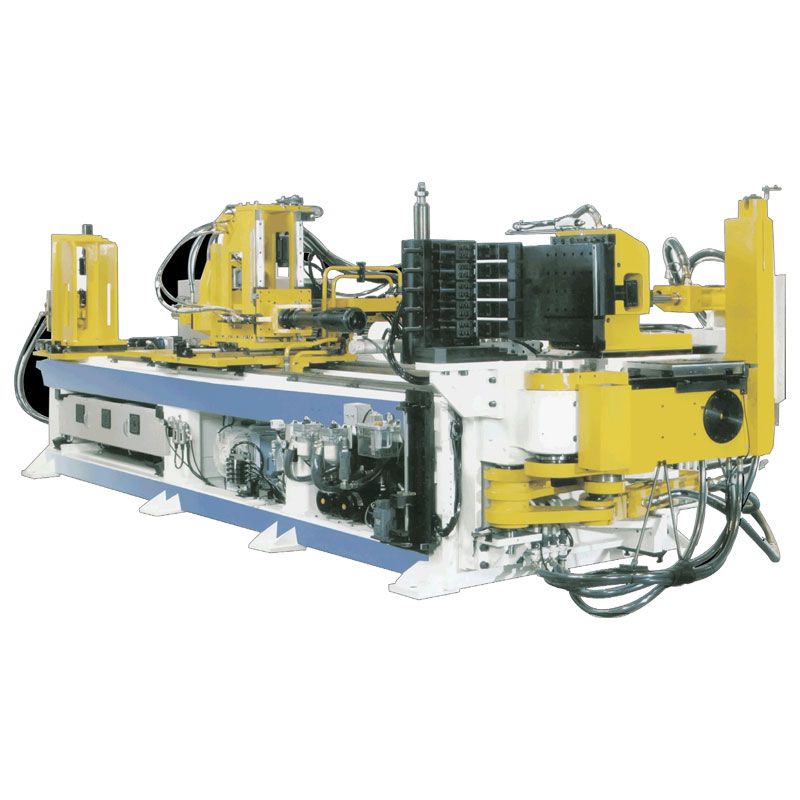

SMS Automatic Pipe Bender

With over a decade of dedication to the pipe bender manufacturing sector, SMS Machinery has integrated imported CNC technology into its automatic pipe bender series.

Browse ProductsCustomized Solutions20 +

Years of Experience

500 +

Machines Delivered

20 +

Country Served

98 %

Customers Satisfaction

Leading Supplier of sheet metal Machinery

For over 25 years, SMS Machinery has been at the forefront of sheet metal machinery, combining innovation with engineering excellence to deliver industry-leading solutions.

- Advanced Technology:Our sheet metal machinery incorporate the latest CNC technology and hydraulic systems for unmatched precision

- Global Presence:With distribution networks across 20+ countries, we provide localized support and service to clients worldwide.

- Quality assurance:All our machines undergo rigorous testing and meet international standards and 48 hours testi

Core Product Features

The SMS Automatic Pipe Bender optimizes its design from multiple dimensions including precision, efficiency, and operation, creating an industrial-grade pipe processing solution.

Request A quoteHigh-Precision Machining

It adopts an imported CNC system, with a pipe bending accuracy of ±0.1mm and high repeat positioning accuracy, meeting the requirements of precision machining.

Fully Automated Operationle

With one-click startup, it automatically completes the processes of material feeding, pipe bending, angle turning, and cutting, reducing manual intervention and lowering labor costs.

Multi-Die Design

It supports free switching between single-layer, double-layer, and triple-layer dies, and is compatible with pipes of different specifications ranging from φ10mm to φ114mm, meeting diverse processing needs.

High-Efficiency Production

The processing efficiency is increased by more than 60% compared with traditional equipment, and it has strong stability in continuous operation, making it suitable for large-batch industrial production.

Intelligent Safety Monitoring

It monitors the equipment's operating status in real time, automatically alarms and displays the cause when a fault occurs, and features a multi-layered safety protection design to ensure operational safety.

High-Strength Frame Design

It is made of high-quality alloy steel through welding, and undergoes annealing treatment to eliminate internal stress. The frame features high rigidity, with a service life of over 10 years.

Main Model

Single pipe bending machine

Auto spare parts (brake oil tube, bumper,muffler,seats,etc.) Motorcycl e manufacturing, fitness equipment, air conditioning refrigeration,bicycle industry, steel furniture, bathroom equipment and other industries.

- ST38/ST38NCφ38

- ST50/ST50NCφ50.8

- ST63/ST63NCφ63.5

- ST75/ST75NCφ76.2

- ST89/ST89NCφ88.9

- ST115/ST115NCφ115

- ST130/ST130NCφ130

- ST168/ST168NCφ168

- ST219/ST219NCφ219

- ST325/ST325NCφ325

NCBL Single pipe bending machine

Adopt PLC+touch screen control imported from taiwan and chinese-english subtitles with easy operation. Adopt servo motor imported from japan+taiwan reduction gears,accurately segment precision, set speed of elbow pipe with its high precision. The angle of elbow pipe can be set for many times in the sixteeth level elbow pipe data setting and stroage. The thin-wall pipes can be bent and manufactured.

- ST38NCBL

- ST50NCBL

- ST63NCBL

- ST75NCBL

- ST89NCBL

- ST115NCBL

- ST130NCBL

- ST168NCBL

CNC Single pipe bending machine

Automatc identification of dynamic characteristics of machine tool/work piece-repid and good processing

- Return the core and boost with trolley - improve the appearance of corner piece.

- The chinese opration prompts + 15 inch true color display+ touch screen - simple and clear opearation.

- The graphical programminh system: the proessing procedure can be obtained upon the vertical tube painting system/modification on the screen - simple, convenient, rapid and accurate programming

- Resilience measurement - the property of batches of pipes can be compared and measured.

- Single-step debugging function- the deformation process of pipes can be comapred and measured.

- Automatic mould drawing--help significantly develop new products.

- Comprehensive monitoring: hydraulic / electrical / drive system, motor phase loss/reversal, voltage, temperature, oil pressure,automatic fault dignosis, passwords, key,records of working hours/number for production management.

- Model: ST25CNC-2A-1S | ST38CNC-2A-1S | ST50CNC-2A-1S

- Model: ST63CNC-2A-1S | ST75CNC-2A-1S | ST89CNC-2A-1S

CNC Single pipe bending machine

Automatc identification of dynamic characteristics of machine tool/work piece-repid and good processing

- Return the core and boost with trolley - improve the appearance of corner piece.

- The chinese opration prompts + 15 inch true color display+ touch screen - simple and clear opearation.

- The graphical programminh system: the proessing procedure can be obtained upon the vertical tube painting system/modification on the screen - simple, convenient, rapid and accurate programming

- Resilience measurement - the property of batches of pipes can be compared and measured.

- Single-step debugging function- the deformation process of pipes can be comapred and measured.

- Automatic mould drawing--help significantly develop new products.

- Comprehensive monitoring: hydraulic / electrical / drive system, motor phase loss/reversal, voltage, temperature, oil pressure,automatic fault dignosis, passwords, key,records of working hours/number for production management.

- Head of multi-mode bending machine can move around, it can automatically changle moulds, and it has high efficiency and high accuracy.

- Model: ST25CNC-3A-2S | ST38CNC-3A-2S | ST50CNC-3A-2S

- Model: ST63CNC-3A-2S | ST75CNC-3A-2S | ST89CNC-3A-2S

CNC Single pipe bending machine

Multi-S series pipe bender is a multi-mode pipe bender, which is equipped with servo motor or proportional servo valve based on different modlels and is capable of multi-axis control, with bending capacity less than 325mm in pipe diameter.

- According to different user needs, multiple bending capacities can be provided, for example,elbow bossting of 1D materials and end bend boosting skill.

- Manufacturing of spare parts for such industries as parts necessary for auto industry,healthy sports equipment, furniture,medical apparatus and instruments,engineering construction machinery and other industries.

- For sets of moulds can be simultaneously loaded to rapidly install and replace different bending radii

- Servo control system,small amount of hydraulic oil, and oil temperature not too high 1-4 layers of bending moulds can be added to CNC 5 axis motor servo control; Early pulling of core can be set for core rod.

- Each layer of moulds can independently control auxiliary boosting speed of guided mould; equipped with adjustable wrinkle-proof plate holder.

- CNC numerical value controls and matches high mechanical accuracy, and improves bending speed and accuracy,

- Direct fedding or feeding by clamping can be chosen.

- Equipped with IPC (industrial computer) and touch control screen

- Can be equipped with interference simulation software, and the operator can input parameters to view if there is any collision or error

- Model:ST63CNC-5A-3S | ST75CNC-5A-3S

- Model:ST89CNC-5A-3S | ST115CNC-5A-3S

Customized Pipe Bending Machine

According to the customer's process requirements, customize pipe bending equipment with special specifications and functions.

Customization ConsultationMain application Area

Frequently Asked Questions (FAQs)

Q: What types of pipe materials are suitable for the SMS pipe bending machine?

A: It is suitable for common metal pipes such as carbon steel, stainless steel, copper, aluminum, and alloys. For special materials, customized dedicated molds and processing parameters are available.

Q: Do you provide equipment installation, commissioning, and technical training?

A: We offer free on-site installation and commissioning services, and provide professional training for customers’ operators on equipment operation, maintenance, and programming to ensure quick mastery of the equipment.

Q: What is the after-sales service period of the equipment?

A: The whole machine comes with a 1-year warranty, and the core components have a 2-year warranty. We provide lifelong maintenance services and spare parts supply. For non-human damage within the warranty period, free repair and replacement are offered.

Q: Can you provide trial processing services for the equipment?

A: We can provide free pipe trial processing services for customers. Customers only need to provide pipe samples and processing requirements, and we will offer trial-processed samples and process plans.